News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2025/02/19 By: Topstar

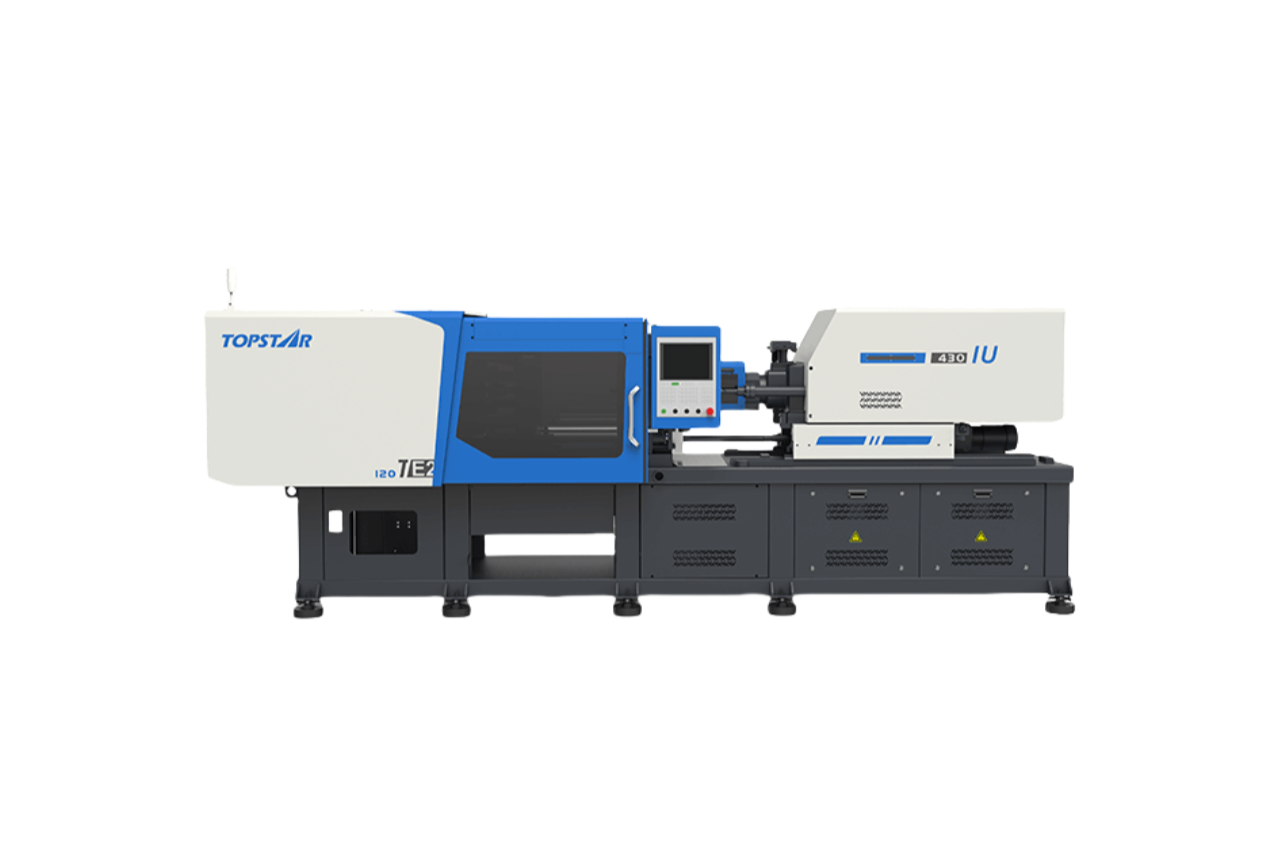

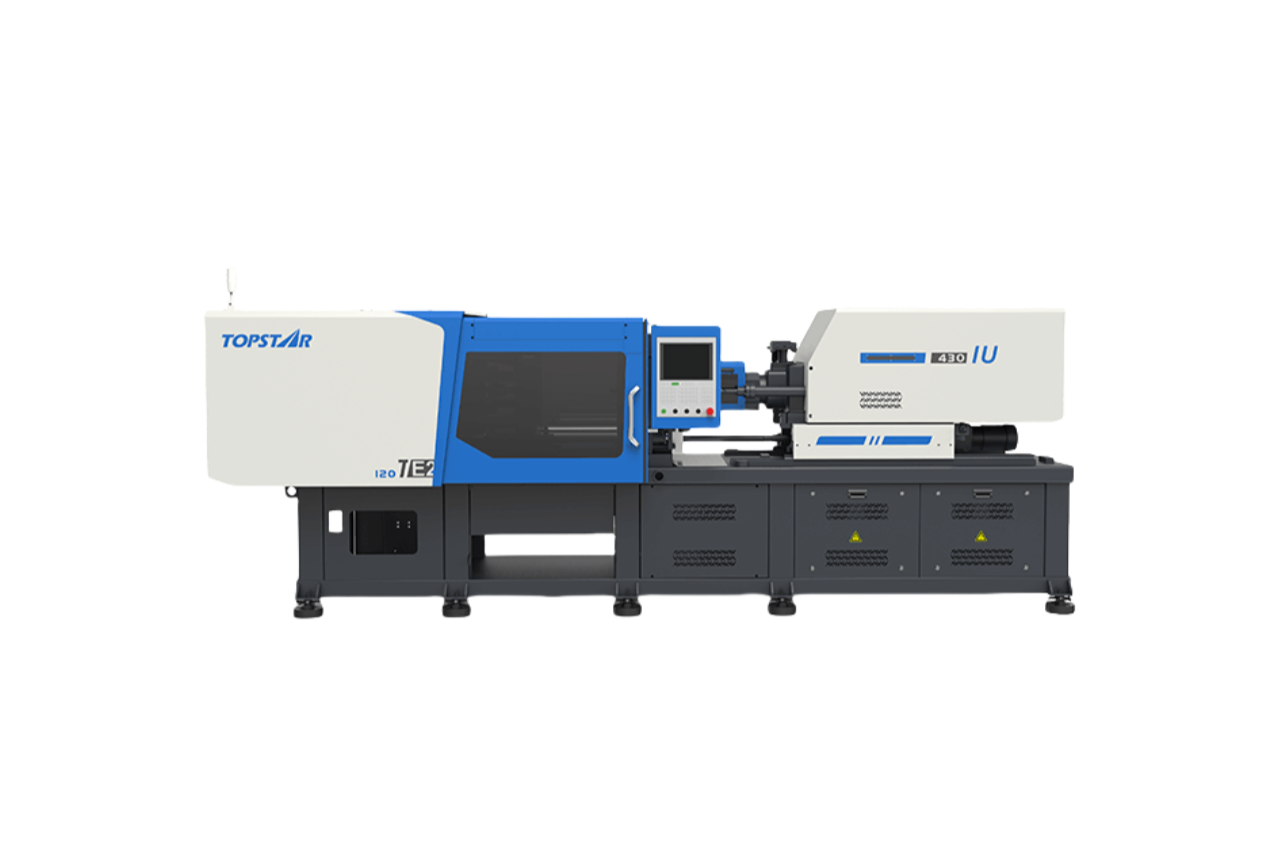

Bringing lower energy consumption injection molding machine solutions to Mexico

Mexico’s manufacturing and injection molding industries have great potential, especially in sectors such as automotive, electronics, and consumer goods, especially in areas close to the US market. Of course, while facing the comprehensive upgrading of manufacturing, some regions of Mexico still face challenges such as unstable or insufficient power supply and a relative shortage of… Continue reading Bringing lower energy consumption injection molding machine solutions to Mexico

-

2025/02/17 By: Topstar

Using Topstar’s plastic injection molding machines to solve production problems for Indian users

India is one of the fastest-growing economies in the world, and its strong market demand for plastic products has also attracted the attention and participation of many global plastic machinery companies. At the same time, for many Indian plastic product manufacturers, production still faces problems such as unstable regional voltage, high demand for energy-saving Injection… Continue reading Using Topstar’s plastic injection molding machines to solve production problems for Indian users

-

2025/02/14 By: Topstar

Plastic Molding Machine Solutions for Faster Turnaround Times

Delays in the injection molding can disrupt the supply chain and increase costs. Due to manual adjustments, traditional plastic molding machines often struggle with inconsistent cycle times, material waste, and frequent downtime. These challenges are exacerbated when customers expect a 20% or more reduction in turnaround time while also keeping defect rates below 5%. Topstar’s… Continue reading Plastic Molding Machine Solutions for Faster Turnaround Times

-

2025/02/12 By: Topstar

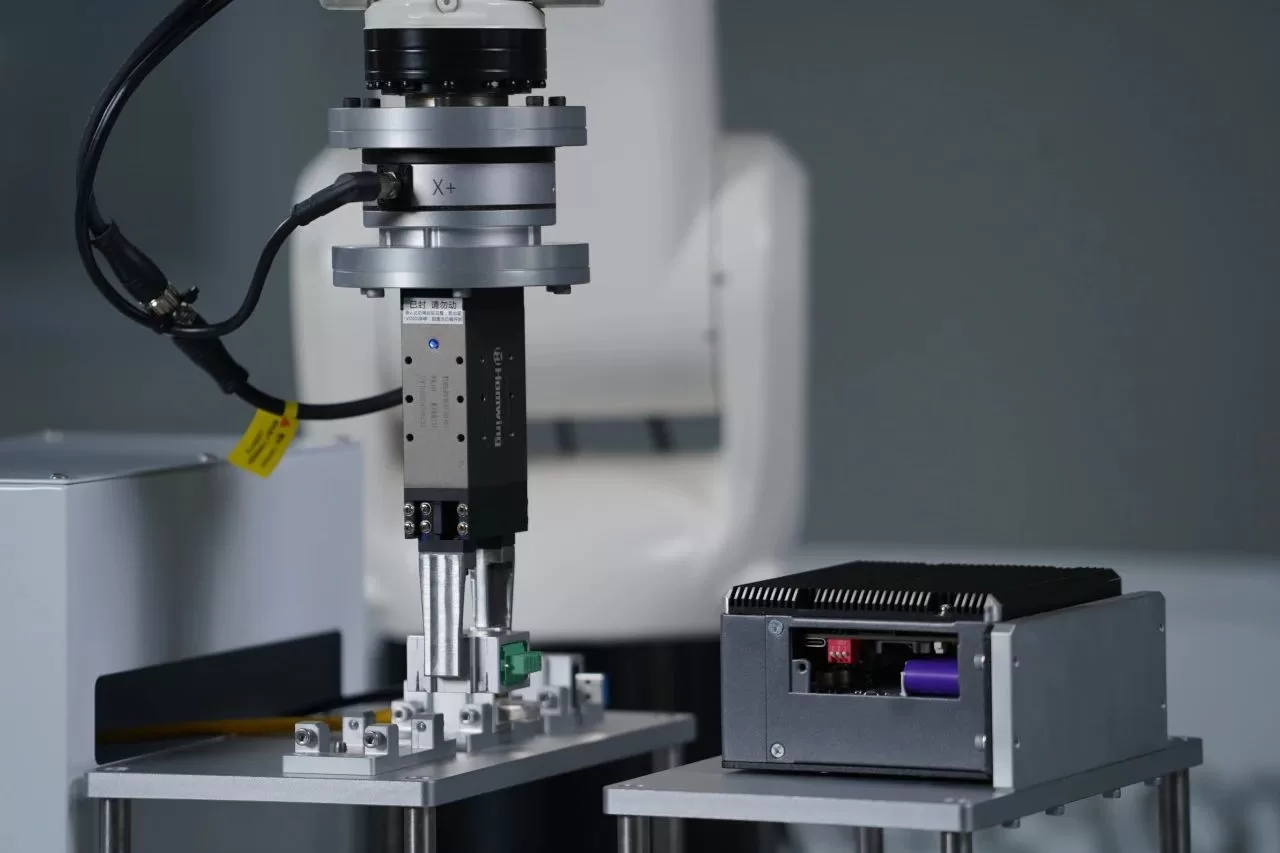

Why is the 5-in-1 servo-driven injection robot better than other injection robots?

Injection robots simplify parts removal, sorting, and post-injection molding operations. However, not all injection molding robots are created equal. Traditional models often suffer from inefficiencies such as limited precision, high energy consumption, and rigid programming frameworks. Topstar’s 5-in-1 servo-driven injection robot is a breakthrough solution that redefines performance through advanced engineering and intelligent design. Integrating… Continue reading Why is the 5-in-1 servo-driven injection robot better than other injection robots?

-

2025/02/10 By: Topstar

How to improve the yield of injection molded parts by using a water chiller?

Other auxiliary equipment is also needed to work to ensure a higher yield rate in the production of plastic parts, in addition to using high-efficiency injection molding machines. Injection molding machines generate very high temperatures when working, especially hydraulic injection molding machines, so in addition to mould temperature controllers, a water chiller is also needed… Continue reading How to improve the yield of injection molded parts by using a water chiller?

-

2025/02/07 By: Topstar

The relationship between mould temperature controller and injection molding efficiency

The accuracy, repeatability, and efficiency of injection moulding determine the profitability of its production. Thermal management bridges the gap between raw materials and perfect final products. A mould temperature controller is key to this thermal regulation, ensuring the mould maintains a precise temperature to optimize cycle time, reduce defects, and increase injection efficiency. Topstar’s fourth-generation… Continue reading The relationship between mould temperature controller and injection molding efficiency

-

2025/02/05 By: Topstar

How to solve the problem of communication delay in electric injection molding machine?

Electric injection molding machines improve the production of plastic manufacturing with precision, energy saving, and high cleanliness. However, a common problem in traditional electric injection molding machines is the communication delay between the controller and the servo drive. This bottleneck affects the quality of high-speed, high-precision applications. Even millisecond delays can lead to inconsistent part… Continue reading How to solve the problem of communication delay in electric injection molding machine?

-

2025/02/03 By: Topstar

How do you avoid mold sticking problems in injection molding machines production?

Injection molding machines enable precise batch production of plastic parts in the production of plastic products. However, one problem that often plagues operators of actual output is mold sticking. That is molded parts stick to the mold cavity or core during the ejection process. This problem not only affects production efficiency but also increases scrap… Continue reading How do you avoid mold sticking problems in injection molding machines production?

-

2025/01/29 By: Topstar

Injection molding machine for medical device production: key factors

Since medical products are sterile and clean, the production environment must be a dust-free workshop. To adapt to the requirements of dust-free workshops, various medical products must use injection molding machines that can reduce the generation of pollutants and complete the injection molding of products. After fully understanding the precision injection molding requirements and dust-free… Continue reading Injection molding machine for medical device production: key factors

-

2025/01/27 By: Topstar

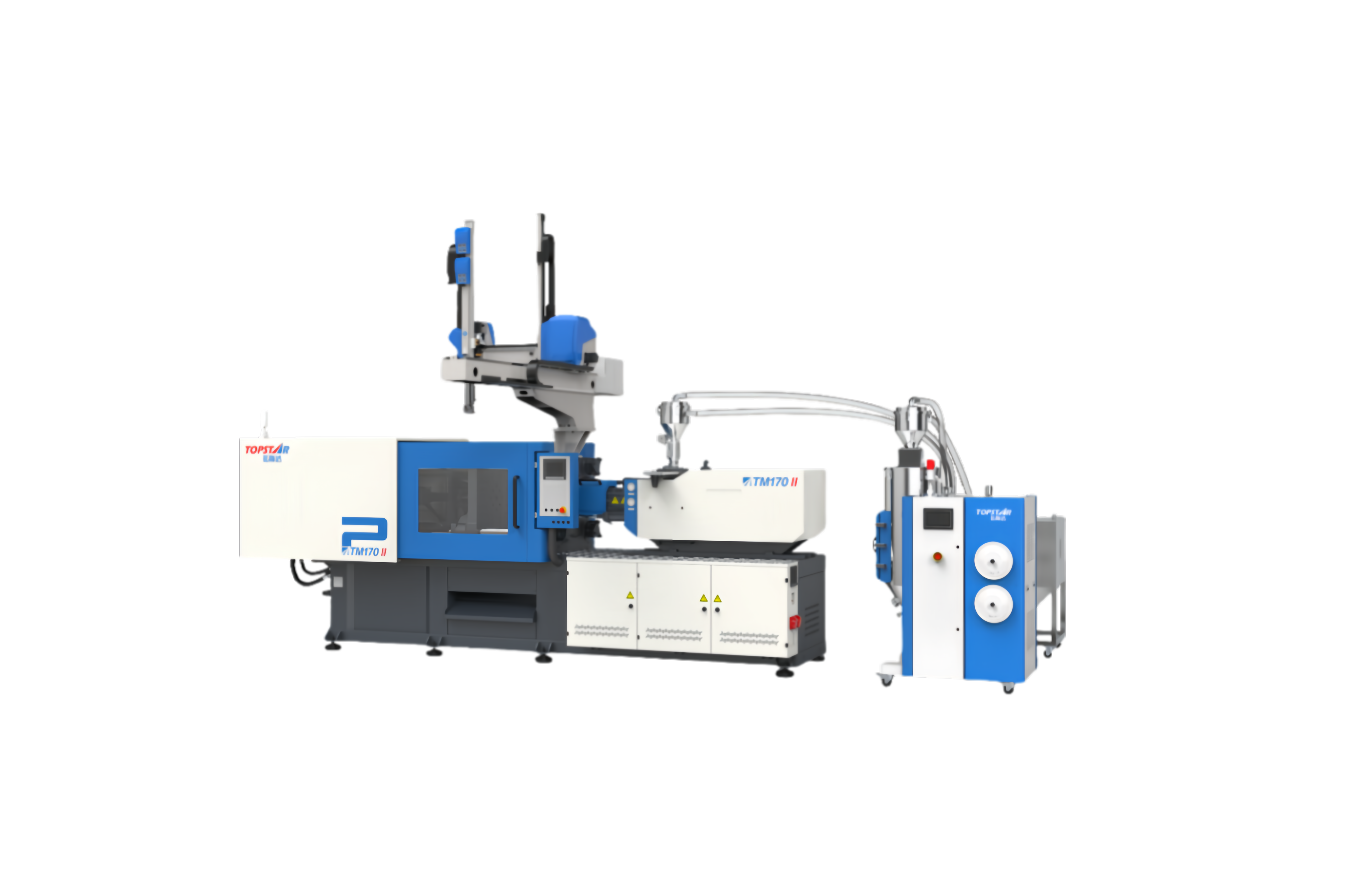

Are there any mould temperature controllers specifically for the automotive industry?

Every component in the automotive industry, whether it is an interior part or a thick-walled product, requires strict moulding standards, especially in terms of temperature control. But is there a mould temperature controller designed specifically for the automotive industry? The answer is yes. This year, Topstar also launched two sets of injection moulding solutions that… Continue reading Are there any mould temperature controllers specifically for the automotive industry?

-

2025/01/24 By: Topstar

New generation industrial robot control platform

The entire industrial control market has problems such as fragmented standards, closed protocols, and difficulty integrating IT and OT systems. There is an urgent need for a standardized, universal, highly stable, and reliable control solution that lowers the threshold for use so that non-industry technicians can easily operate and maintain it. This year, the new… Continue reading New generation industrial robot control platform

-

2025/01/22 By: Topstar

How do plastic injection molding machines process various plastic raw materials?

In 2024, Topstar launched special plastic injection molding machines for MIM injection molding to address the difficulties of metal injection molding. At the same time, it also launched two innovative solutions for the automotive lighting industry: automotive lighting silicone headlight dual-material and automotive PMMA thick-walled headlight injection molding unique solutions. In these two solutions, the… Continue reading How do plastic injection molding machines process various plastic raw materials?