News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2025/03/19 By: Topstar

How to Solve Uneven Drying in Injection Molding with a Dehumidifying Dryer?

When processing engineering plastics, uneven drying can lead to defects, compromised structural integrity, and inconsistent final product performance. Traditional drying methods often rely on ambient heat or simple forced ventilation systems that do not provide consistent results, especially when processing complex engineering plastics. Variations in moisture content and temperature fluctuations can lead to uneven drying,… Continue reading How to Solve Uneven Drying in Injection Molding with a Dehumidifying Dryer?

-

2025/03/17 By: Topstar

How do EU sustainability regulations affect the choice of plastic molding machines?

The EU Sustainable Development Directive aims to reduce environmental impact by encouraging the use of environmentally friendly materials and processes. For the plastics industry, this means a shift from traditional materials to advanced thermosets and thermoplastics that are lighter, stronger, and more recyclable. Therefore, plastic manufacturers in the European region are under pressure to innovate… Continue reading How do EU sustainability regulations affect the choice of plastic molding machines?

-

2025/03/14 By: Topstar

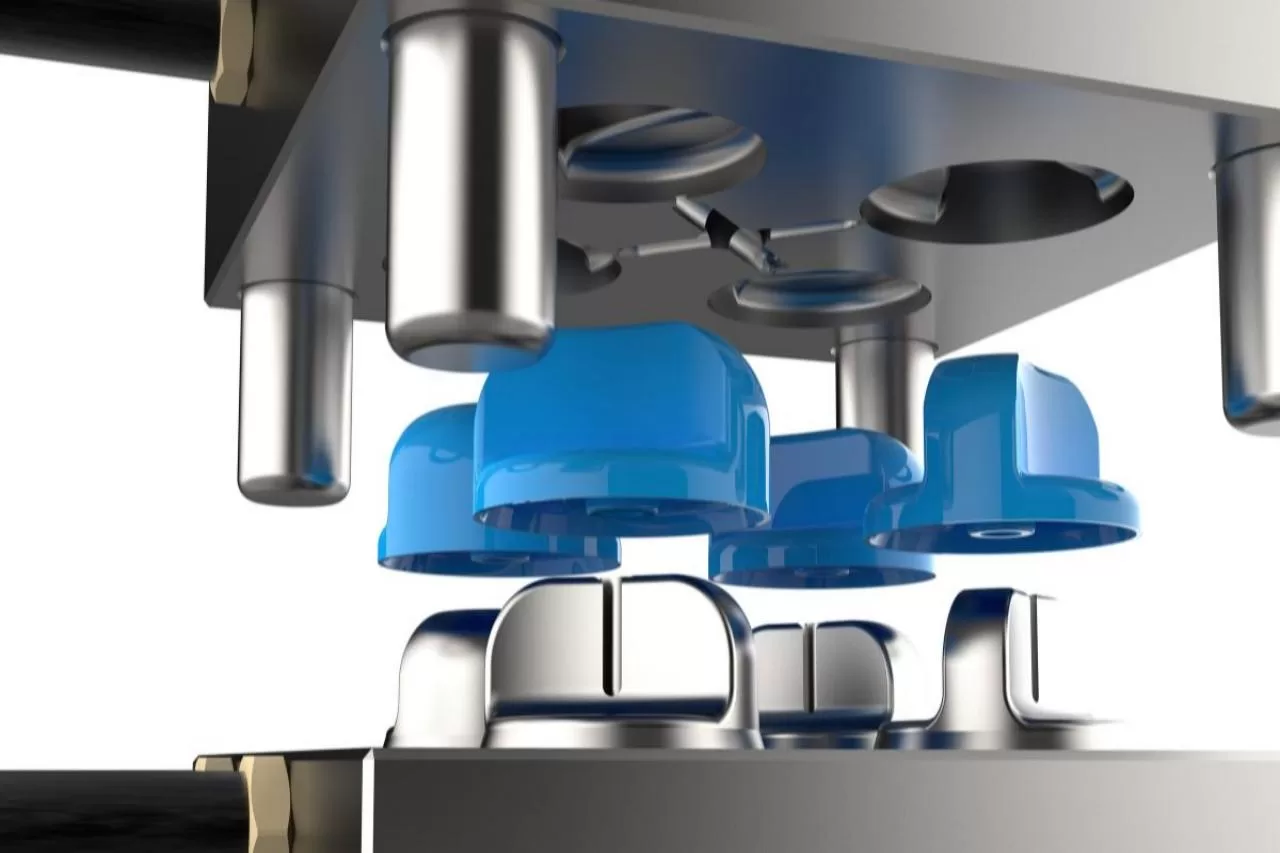

How can we improve the safety of the injection robot during operation?

In injection molding operations that require high speed and high precision, these injection robots are prone to torque overloads – that is, the torque applied during operation exceeds the preset value. This situation can cause a series of safety issues, including potential damage to the mold, ejector pins, and even the final product itself. The… Continue reading How can we improve the safety of the injection robot during operation?

-

2025/03/12 By: Topstar

How to avoid the strain on the plastic injection molding machine?

In the clamping unit of a plastic injection molding machine, tie rods are responsible for holding the two halves of the mold together under high clamping forces. However, the friction generated by continuous motion and the necessity for lubrication can cause the coring rods to be overstressed and eventually fail, which occurs when excessive friction… Continue reading How to avoid the strain on the plastic injection molding machine?

-

2025/03/10 By: Topstar

Improving injection molding performance at North American sites with Topstar’s water chiller solutions

Injection molding plants across North America often face high energy costs when using water chillers. Some traditional water chillers are inefficient, resulting in a surge in operating expenses. In addition, hard water in some parts of North America (such as the Great Lakes) causes scale accumulation that results in a 20%-30% drop in heat transfer… Continue reading Improving injection molding performance at North American sites with Topstar’s water chiller solutions

-

2025/03/07 By: Topstar

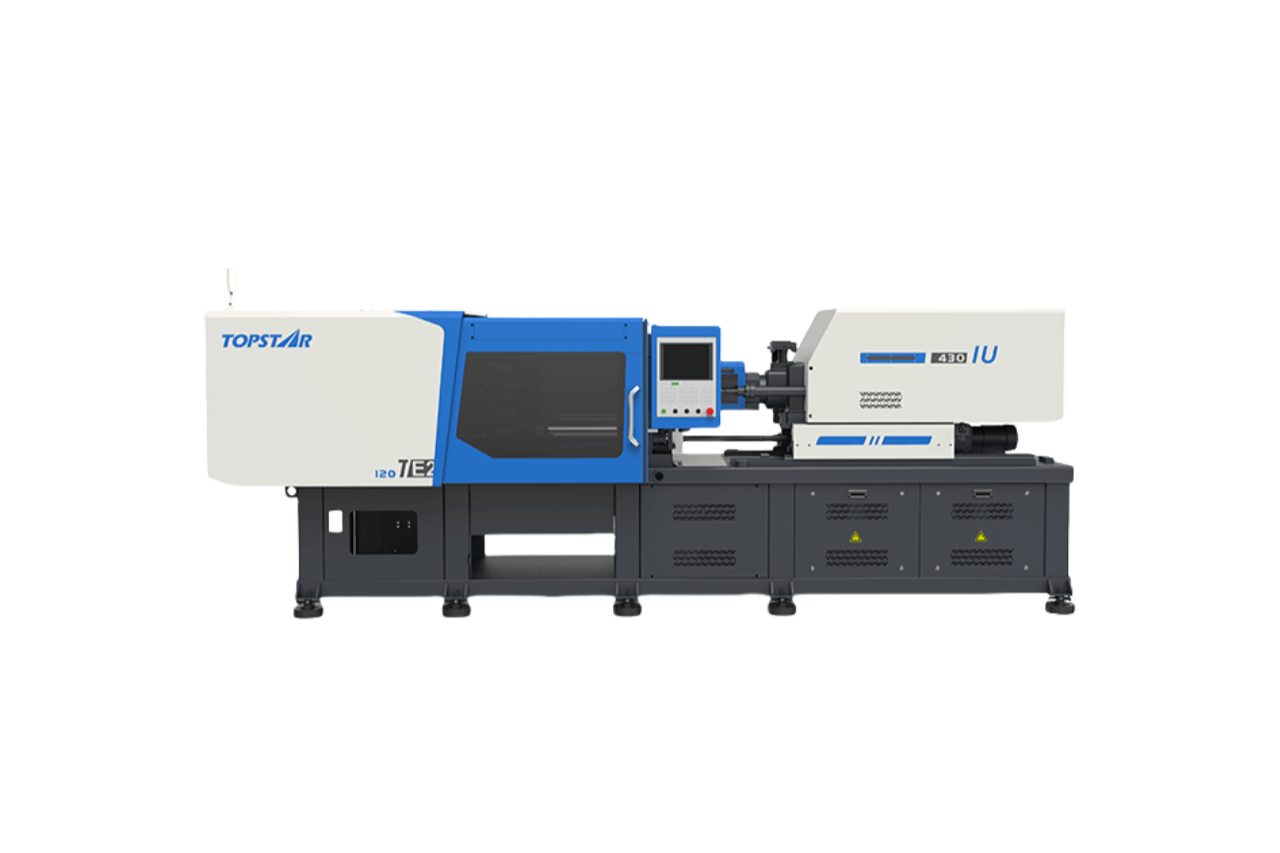

How to use Topstar injection molding machine to realize smart manufacturing technology?

Intelligent manufacturing is the development trend of the manufacturing industry, and the cornerstone of Topstar’s smart manufacturing strategy is the concept of open injection molding machine control systems. Traditional injection molding machine usually operate as isolated units with limited interaction between components and minimal flexibility in adapting to different production requirements. At Topstar, we have… Continue reading How to use Topstar injection molding machine to realize smart manufacturing technology?

-

2025/03/05 By: Topstar

Why do North American manufacturers choose Topstar mould temperature controllers for temperature control?

Plastics manufacturers in North America evaluate mould temperature controllers based on their ability to maintain stable temperatures during voltage fluctuations and ambient temperature changes. This level of stability is critical to avoiding product warping or shrinkage, which can lead to costly defects and production downtime. At the same time, they also require accuracy and long-term… Continue reading Why do North American manufacturers choose Topstar mould temperature controllers for temperature control?

-

2025/03/03 By: Topstar

Intelligent transformation of injection molding machines: How to cope with the Spanish injection molding market?

Demand in Spain is focused on large, high-precision and high-efficiency injection molding machines for producing automotive parts, including interior components, electronic components and lightweight plastic parts. However, rising labor costs and the need for faster and more reliable production have driven the market towards integrated intelligent solutions. To this end, Topstar has taken the lead… Continue reading Intelligent transformation of injection molding machines: How to cope with the Spanish injection molding market?

-

2025/02/28 By: Topstar

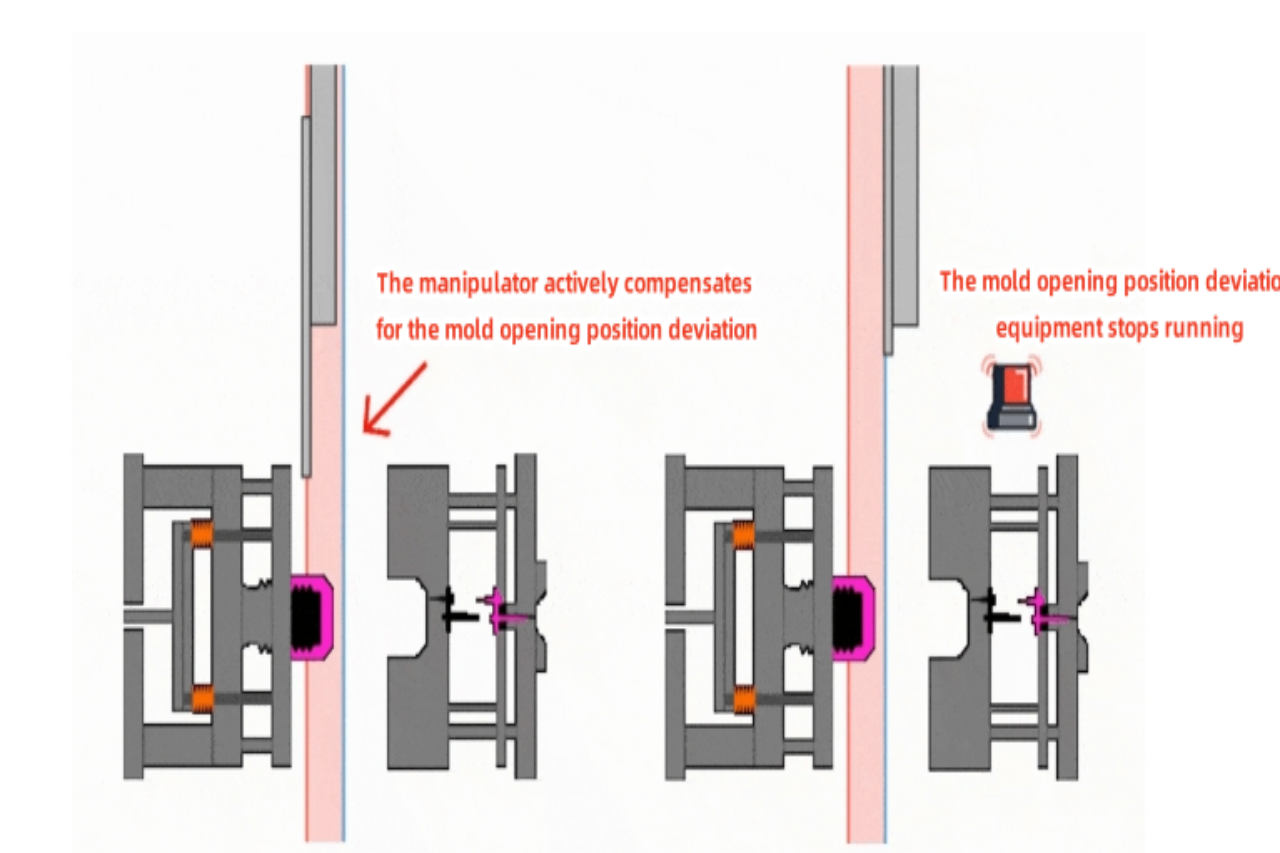

Topstar’s injection molding robot calibration fixes ejection position deviation and suction time inconsistency

In traditional injection molding, problems such as deviation of the ejection position and inconsistency of the suction time of the injection molding robot occur. At the same time, signal delays, poor compatibility, and low stability between devices lead to production delays, equipment failures, and resource waste. Topstar provides a modern and intelligent solution through the… Continue reading Topstar’s injection molding robot calibration fixes ejection position deviation and suction time inconsistency

-

2025/02/26 By: Topstar

Industrial robots: Achieving 0.01mm precision intelligent sorting

As core equipment in the manufacturing industry, industrial robots are becoming increasingly important and a key force in shaping the future of manufacturing. With the continuous advancement of technology, pursuing precision requires high-precision tasks (such as sorting with an accuracy of 0.01 mm) in some specific industries. Topstar’s innovative combination of industrial robots with the… Continue reading Industrial robots: Achieving 0.01mm precision intelligent sorting

-

2025/02/24 By: Topstar

How can Topstar plastic injection molding machine help European countries solve injection molding problems?

Challenges such as rising energy costs, an aging workforce, and increased competition from low-cost Asian manufacturers have put tremendous pressure on European manufacturers, especially in industries such as injection molding. Due to various environmental issues, these countries face severe economic dislocation, which has caused energy prices to soar. Injection molding is energy-intensive, and rising costs… Continue reading How can Topstar plastic injection molding machine help European countries solve injection molding problems?

-

2025/02/21 By: Topstar

How to Improve the Yield Rate of Injection Molded Parts by Cooling with a water chiller

Maintaining high yields and ensuring the quality of molded parts during injection molding can be challenging, as injection molding machines generate high temperatures when operating, which can lead to problems such as overheating, warping, or material defects. In this article, we will explore how using a water chiller for cooling can significantly improve the yield… Continue reading How to Improve the Yield Rate of Injection Molded Parts by Cooling with a water chiller