News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2024/11/08 By: Topstar

How do injection molding machine manufacturers help smart manufacturing?

Intelligent manufacturing uses data, automation and digital technology to optimize production and improve efficiency, thus changing the global manufacturing industry. Under the influence of worldwide digitalization and intelligence, as injection molding machine manufacturers, we have received feedback from many customers and collected specific smart equipment requirements from clients in different countries and regions. These requirements… Continue reading How do injection molding machine manufacturers help smart manufacturing?

-

2024/11/06 By: Topstar

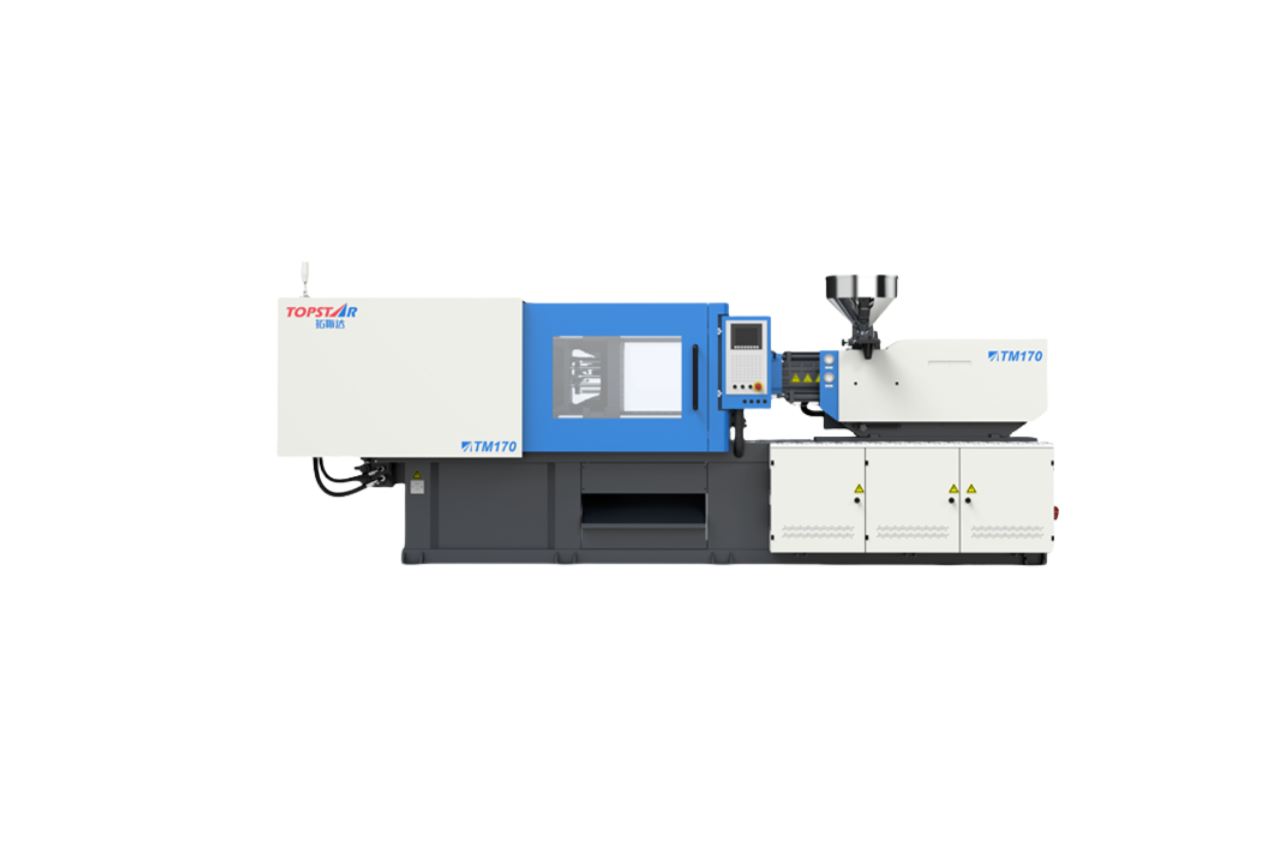

How to improve the stability of horizontal injection molding machine?

Horizontal injection molding machine is one of the core equipment of many injection molding factories. Different types of horizontal injection molding machines will bring different precision and efficiency. When using some traditional injection molding machines, you may face the situation of the injection molding process not being stable enough and having a high defective rate.… Continue reading How to improve the stability of horizontal injection molding machine?

-

2024/11/04 By: Topstar

How to make injection molding easier through injection molding machines?

Faced with changes in market demand for injection molding machines and upgrades in injection molding processes, customers are increasingly concerned about the stability, quality, and delivery of these machines, as well as whether they can enhance their manufacturing capabilities and provide more reliable services. What unique value and performance can Topstar offer to its customers?… Continue reading How to make injection molding easier through injection molding machines?

-

2024/11/01 By: Topstar

Provide integrated injection molding machine solutions for different customers

With the rise of the auto parts, medical, and optical products industries, the corresponding manufacturing industry is facing intense competition, and the demand for injection molding machine efficiency, precision, and adaptability is higher than ever. In the face of different overseas countries, Topstar can know the challenges they face in injection molding and can provide… Continue reading Provide integrated injection molding machine solutions for different customers

-

2024/10/30 By: Topstar

How to integrate mold temperature controller with existing system?

The right mold temperature is required to produce high-quality parts during the injection molding process. In injection molding equipment, mold temperature controllers can play a role in maintaining optimal temperature, directly affecting the quality of molded products. Some injection moulding workshops cannot integrate the mold temperature controller with the existing injection moulding system, making production… Continue reading How to integrate mold temperature controller with existing system?

-

2024/10/28 By: Topstar

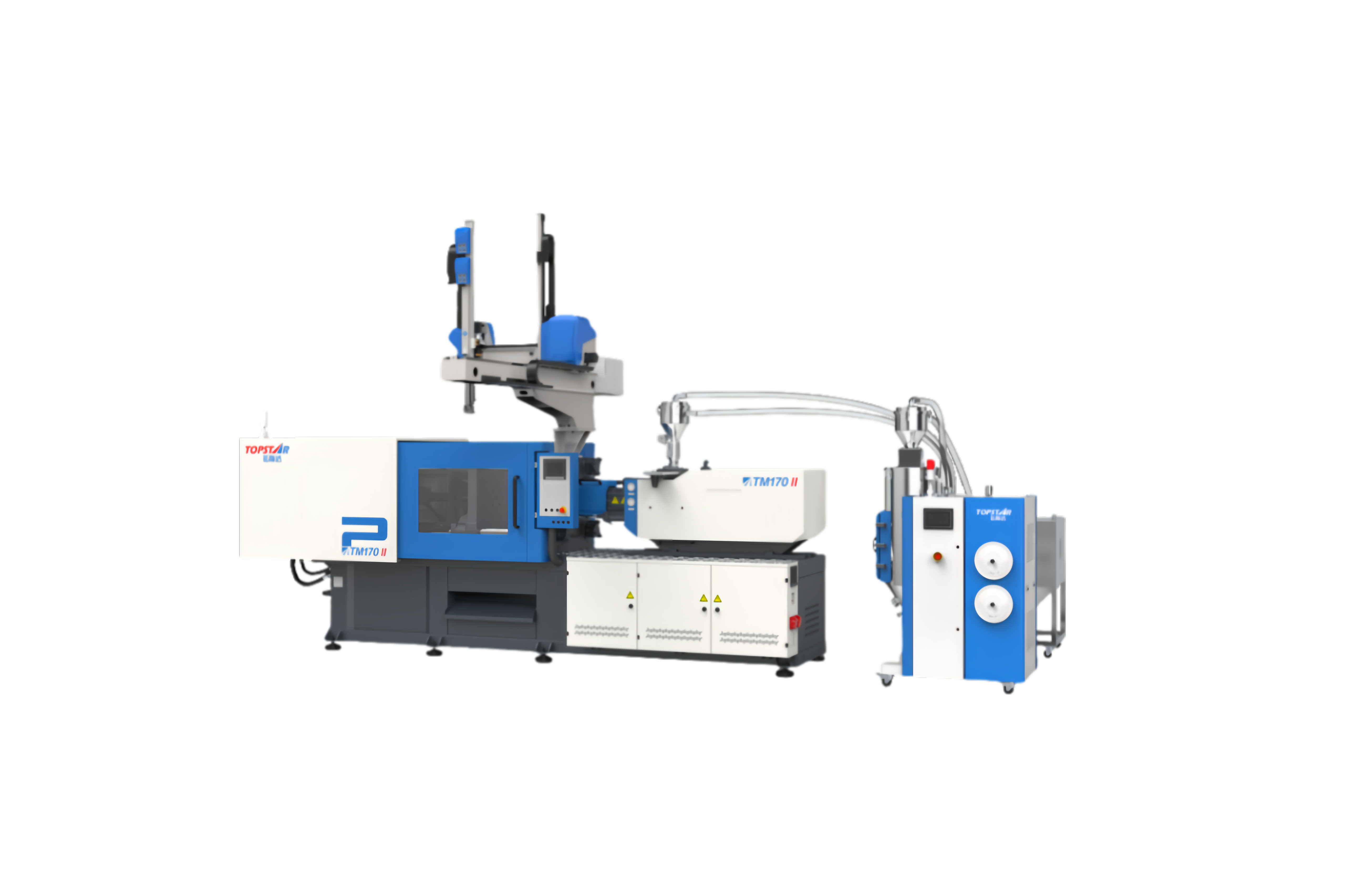

Innovative technologies and concepts provided by leading injection molding machine manufacturer

Topstar is an injection molding machine manufacturer with industrial robots, injection molding machines, CNC, and auxiliary equipment as its core. We have three core technologies, control, servo, and vision, to create an intelligent hardware platform driven by core technologies, providing smart factory overall solutions for different manufacturing companies. On this basis, to make injection molding… Continue reading Innovative technologies and concepts provided by leading injection molding machine manufacturer

-

2024/10/25 By: Topstar

How do you reduce your production costs with an injection molding machine?

Some large manufacturing companies are faced with the problem of unnecessary production costs, which will affect not only the output but also the final revenue. On the one hand, there is an increase in labour costs, and on the other hand, there is an impact on equipment performance, so this problem must be solved fundamentally.… Continue reading How do you reduce your production costs with an injection molding machine?

-

2024/10/23 By: Topstar

Using electric injection molding machines to optimize customer production management

Every plastic product manufacturer pays attention to production management because the efficiency of production management affects the production capacity and the final benefits of the entire injection molding workshop. Therefore, manufacturers of various plastic products are continually seeking to optimize injection molding production and implement efficient solutions to enhance production efficiency and quality. At Tosda,… Continue reading Using electric injection molding machines to optimize customer production management

-

2024/10/21 By: Topstar

What are the latest advancements in injection molding robot technology?

Analysts expect the injection molding robot market to grow by $109.2 million between 2023 and 2028, with a CAGR of 4.36%. Driven by the increased productivity and efficiency brought about by intelligence and various advanced technologies, the functions of these robots are constantly expanding, providing different manufacturers with innovative solutions to meet the needs of… Continue reading What are the latest advancements in injection molding robot technology?

-

2024/10/18 By: Topstar

How do mold temperature controller handle thermal overloads?

In plastic product manufacturing, precise temperature control allows the production of high-quality parts. Mold temperature controllers are critical to maintaining a constant temperature during injection molding. These devices regulate the mold’s temperature to ensure it remains within the optimal operating parameters, improving part quality and production efficiency. However, when exposed to excessive temperatures, thermal overloads… Continue reading How do mold temperature controller handle thermal overloads?

-

2024/10/16 By: Topstar

What options are available for enhancing the flexibility of all electric injection molding machine?

An all electric injection molding machine has become the best choice for the current manufacturing industry’s pursuit of efficiency, precision, and sustainability. These machines can produce high-quality parts while minimizing energy consumption and reducing environmental pollution. However, to fully utilize the advantages of all-electric systems in injection molding, it is necessary to increase their flexibility… Continue reading What options are available for enhancing the flexibility of all electric injection molding machine?

-

2024/10/14 By: Topstar

How does a mould temperature controller contribute to reducing scrap rates?

The high scrap rate in the injection moulding process and the frequent occurrence of scrap will greatly affect the production efficiency and product quality of the entire workshop. Therefore, reducing the scrap rate can maintain profitability and improve production efficiency. Many factors can affect the occurrence of scrap rate in this injection moulding process, such… Continue reading How does a mould temperature controller contribute to reducing scrap rates?