News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2024/09/09 By: Topstar

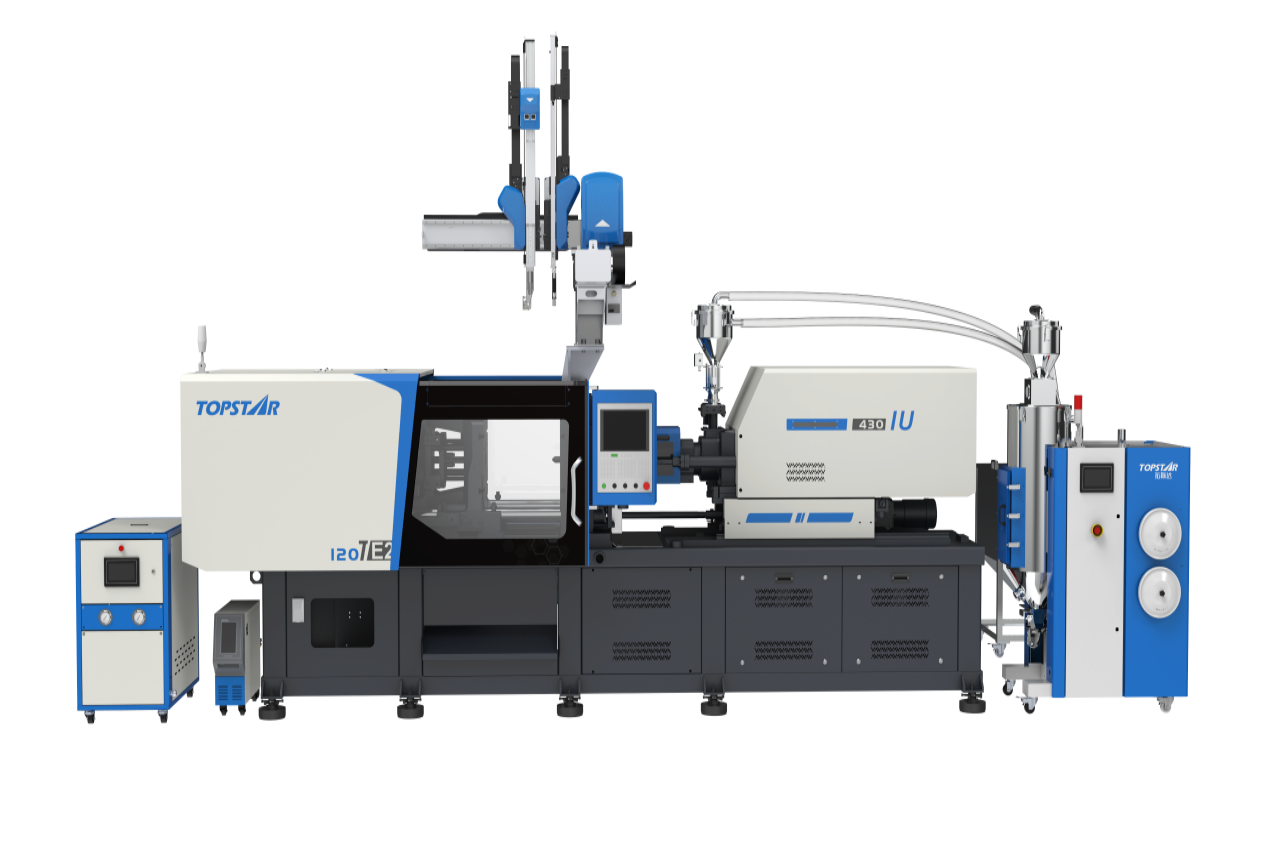

The overall solution for the injection molding machine of medicine bottle caps

There are strict regulations and quality requirements for procuring medicine bottle caps in the pharmaceutical industry, so when producing medicine bottle caps, it is necessary to use a dedicated injection molding machine. These caps not only seal the medicine bottles but also ensure product safety, tamper-proof, and meet strict hygiene standards. At Topstar, we can… Continue reading The overall solution for the injection molding machine of medicine bottle caps

-

1-jpg.webp)

2024/09/06 By: Topstar

How do injection molding machine manufacturers provide intelligent injection molding solutions?

What distinguishes Topstar from other injection molding machine manufacturers is that it provides users with not only injection molding machines but also intelligent injection molding solutions. Industry 4.0 makes the injection molding industry and other manufacturing industries more intelligent, so we not only make products intelligent but also make users’ factory workshops intelligent. Intelligent injection… Continue reading How do injection molding machine manufacturers provide intelligent injection molding solutions?

-

2024/09/04 By: Topstar

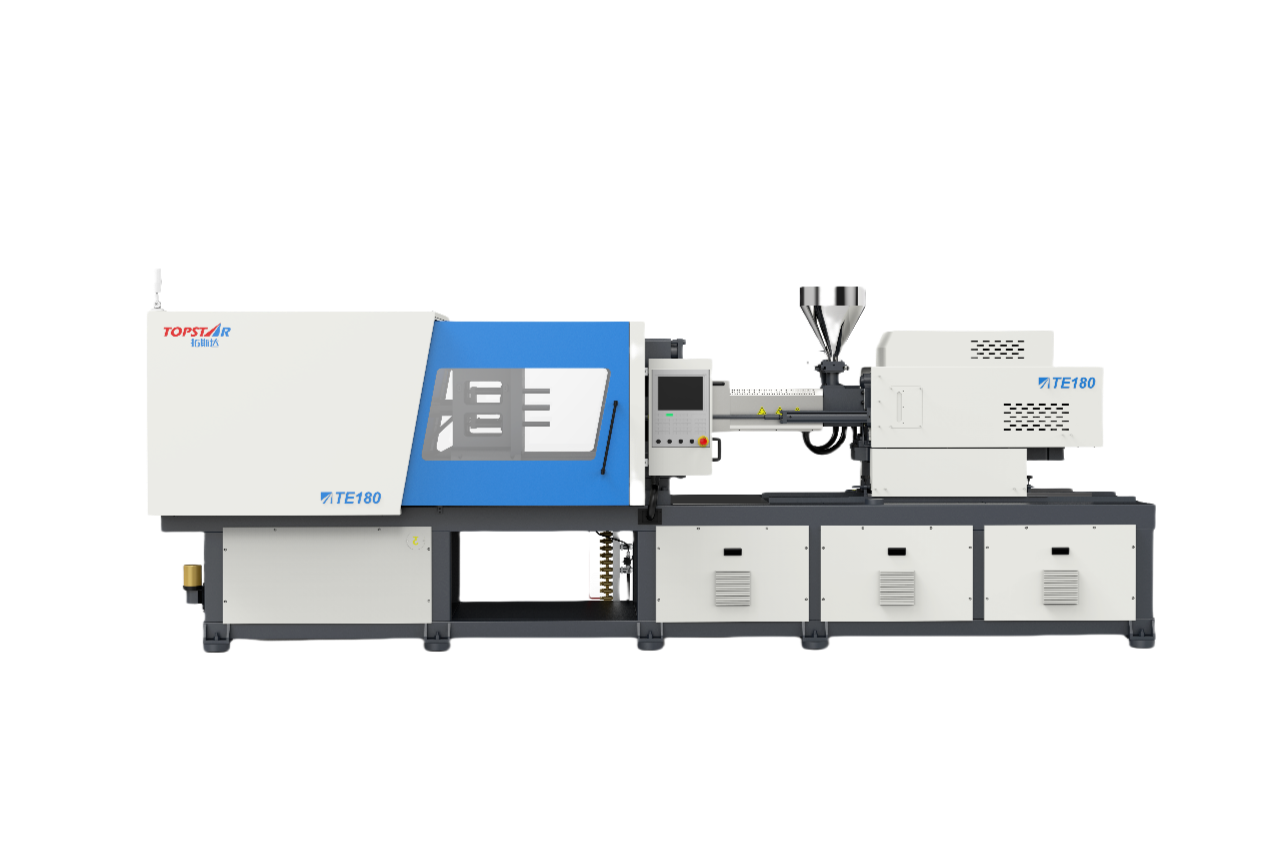

Electric injection molding machine solutions for the medical field

All products in the medical field must meet strict quality control standards, precision, and cleanliness. When providing injection molding solutions to customers in the medical field, an electric injection molding machine is used to meet strict quality standards, ensure cost-effectiveness, and develop a comprehensive injection molding turnkey plan for you. In this article, we will… Continue reading Electric injection molding machine solutions for the medical field

-

2024/09/02 By: Topstar

How to select the right injection speed for a hydraulic injection molding machine?

The correct injection speed in the process of injection molding can ensure the quality and efficiency of the production process. The injection speed determines the speed at which the molten plastic is injected into the mold, and plays a key role in the final characteristics of the molded part. Injection speed is also a parameter… Continue reading How to select the right injection speed for a hydraulic injection molding machine?

-

2024/08/28 By: Topstar

What are the most important specifications for a plastic injection molding machine?

Injection molding is the core manufacturing process for making various plastic products involving multiple industries, such as automobiles, electronics, consumer products, and medical devices. The efficiency and precision of the plastic injection molding machine you choose will significantly impact the product’s quality, production speed, and cost. So, when you purchase a batch of plastic injection… Continue reading What are the most important specifications for a plastic injection molding machine?

-

2024/08/26 By: Topstar

Phone case making machine that ensures a uniform thickness of mobile phone cases

In the mobile phone accessories market, consistency of product quality is a key factor affecting user retention. Then, one of the factors affecting the quality and durability of mobile phone cases is their uniform thickness. Uniform thickness ensures that the mobile phone case fits perfectly with the phone, enhancing its protection performance, aesthetics and overall… Continue reading Phone case making machine that ensures a uniform thickness of mobile phone cases

-

2024/08/23 By: Topstar

How to achieve high-strength parts with injection molding machines?

The injection molding process requires more than basic molding capabilities when making high-strength parts. Achieving high-strength components requires careful consideration of various factors, including material selection, injection molding machine accessory settings, mold design, and post-processing techniques. In this article, we will share how to achieve high-strength parts using Topstar’s injection molding machines and the methods… Continue reading How to achieve high-strength parts with injection molding machines?

-

2024/08/21 By: Topstar

How to ensure uniform temperature distribution with a mold temperature controller?

Temperature changes in the mould during injection moulding can lead to part defects, such as warping, dents, and dimensional inconsistencies that compromise the integrity of the final product. Mold temperature controllers, as injection molding auxiliary equipment, are indispensable devices in a complete production line. This ensures that the mold maintains the desired temperature throughout the… Continue reading How to ensure uniform temperature distribution with a mold temperature controller?

-

2024/08/19 By: Topstar

What are the typical energy savings of an all electric injection molding machine?

Throughout the injection molding production process, people are concerned about quality efficiency and energy conservation during the molding process. Rising energy costs and growing environmental concerns are prompting manufacturers to pursue more sustainable and cost-effective production methods. The all electric injection molding machine has the best energy-saving effect in injection molding, and they can save… Continue reading What are the typical energy savings of an all electric injection molding machine?

-

2024/08/16 By: Topstar

How can EU series injection molding robots shorten cycle time?

Reducing cycle time is key to achieving higher production and reducing operating costs for manufacturers. When faced with large-volume production tasks, some traditional injection molding robots cannot achieve fast grasping work, and there will be situations such as empty grasping and stopping, which cannot achieve a shortened cycle time. Topstar has developed the EU series… Continue reading How can EU series injection molding robots shorten cycle time?

-

2024/08/14 By: Topstar

Injection molding equipment suitable for the production of plastic daily necessities

Plastic products occupy a large part of our lives, whether our home life or office supplies. They bring us a lot of convenience. Injection molding has also become the core technology for producing various daily necessities. It can provide the precision required to meet the needs of modern consumers and the efficiency and scalability required… Continue reading Injection molding equipment suitable for the production of plastic daily necessities

-

2024/08/12 By: Topstar

How to control viscosity in electric injection molding machine of medical products?

When manufacturing high-precision medical products, controlling the viscosity during injection molding can ensure the quality of the finished product. Medical products have very high standards for cleanliness and precision so that everyone will choose an electric injection molding machine as the core machine in the production process. In this article, we will share how Topstar’s… Continue reading How to control viscosity in electric injection molding machine of medical products?