News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2025/04/16 By: Topstar

How to use a plastic molding machine to achieve a closed loop of the entire production process?

In the injection molding manufacturing industry, which advocates cost reduction and efficiency improvement, integrated closed-loop production processes can maximize efficiency, reduce waste, and maintain stable production. To help customers achieve the full process of high-speed closed-loop production, injection molding machines with integrated injection molding processes are used. These machines can work with surrounding auxiliary equipment… Continue reading How to use a plastic molding machine to achieve a closed loop of the entire production process?

-

2025/04/11 By: Topstar

How to use water chiller to achieve efficient and energy-saving injection molding cooling?

The role of the water chiller is to regulate the mold temperature during the injection molding process to prevent defects such as warping or long cycle times. In injection molding, the cooling process is as vital as the molding process. Efficient cooling ensures high-quality parts, faster production cycles, and significant energy savings; for manufacturers pursuing… Continue reading How to use water chiller to achieve efficient and energy-saving injection molding cooling?

-

2025/04/09 By: Topstar

How to solve the problem of excessive vibration of injection molding robot?

Injection molding robots can achieve efficient operation, high-precision grasping, and other tasks in injection molding. Suppose your injection molding robot is not installed firmly, or the overall design is imperfect during molding. In that case, excessive vibration will occur, resulting in inaccurate grasping, affecting product quality, shortening machine life, and ultimately affecting overall productivity. This… Continue reading How to solve the problem of excessive vibration of injection molding robot?

-

2025/04/07 By: Topstar

How do I troubleshoot a temperature sensor failure in a mold temperature controller?

The mold temperature controller is the core of maintaining a stable and efficient injection molding process. Its temperature sensors monitor and report real-time data to the controller, allowing the controller to adjust the heating and cooling systems accordingly. However, when a temperature sensor fails, the feedback loop is interrupted, and the mold temperature control system… Continue reading How do I troubleshoot a temperature sensor failure in a mold temperature controller?

-

2025/04/04 By: Topstar

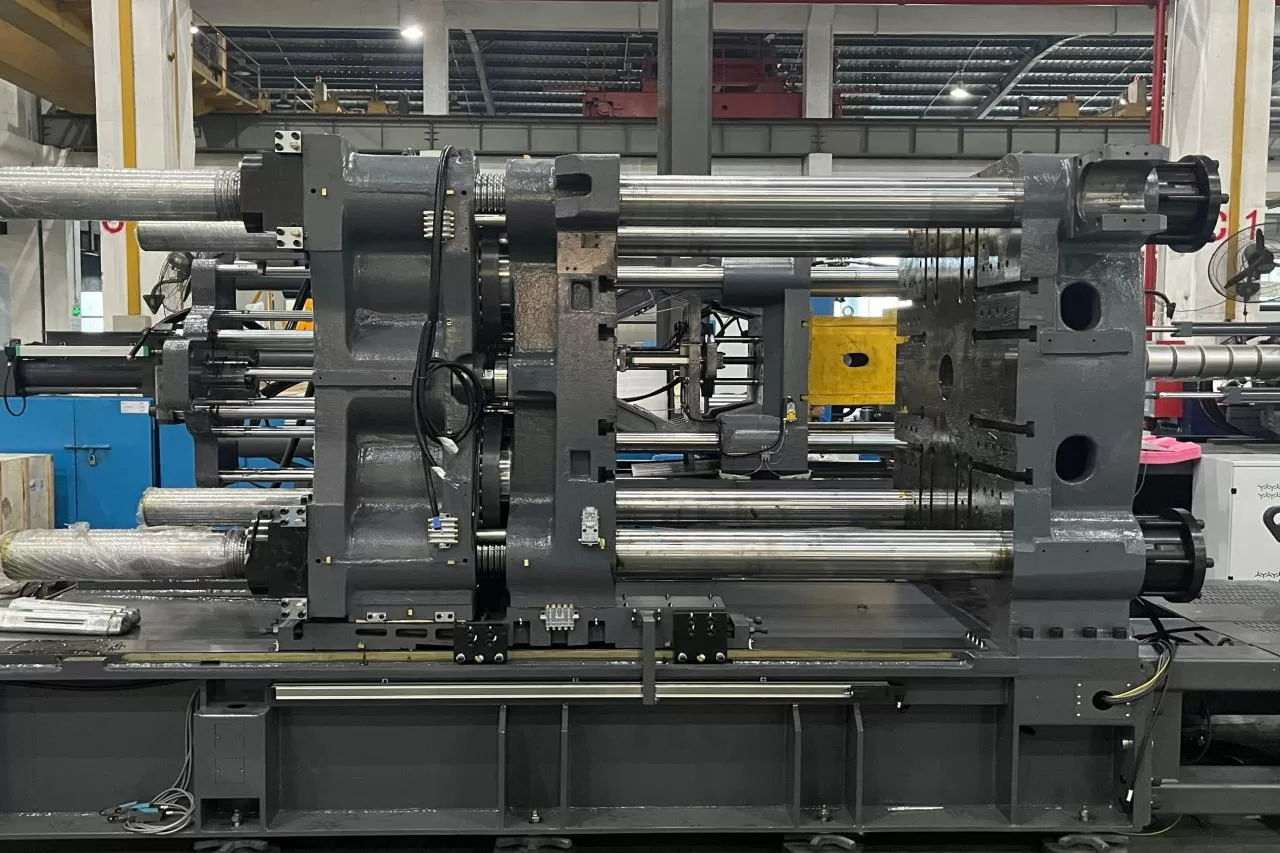

What are the development and future prospects of injection molding machines?

Injection molding machines are at the heart of mass injection molding production in automotive, consumer goods, electronics, and medical devices. The current state of intelligence in injection molding machines is driven by rapid technological advancement, digital integration, and evolving process control. Modern injection molding machines are no longer mechanical devices; they have evolved into equipment… Continue reading What are the development and future prospects of injection molding machines?

-

2025/04/02 By: Topstar

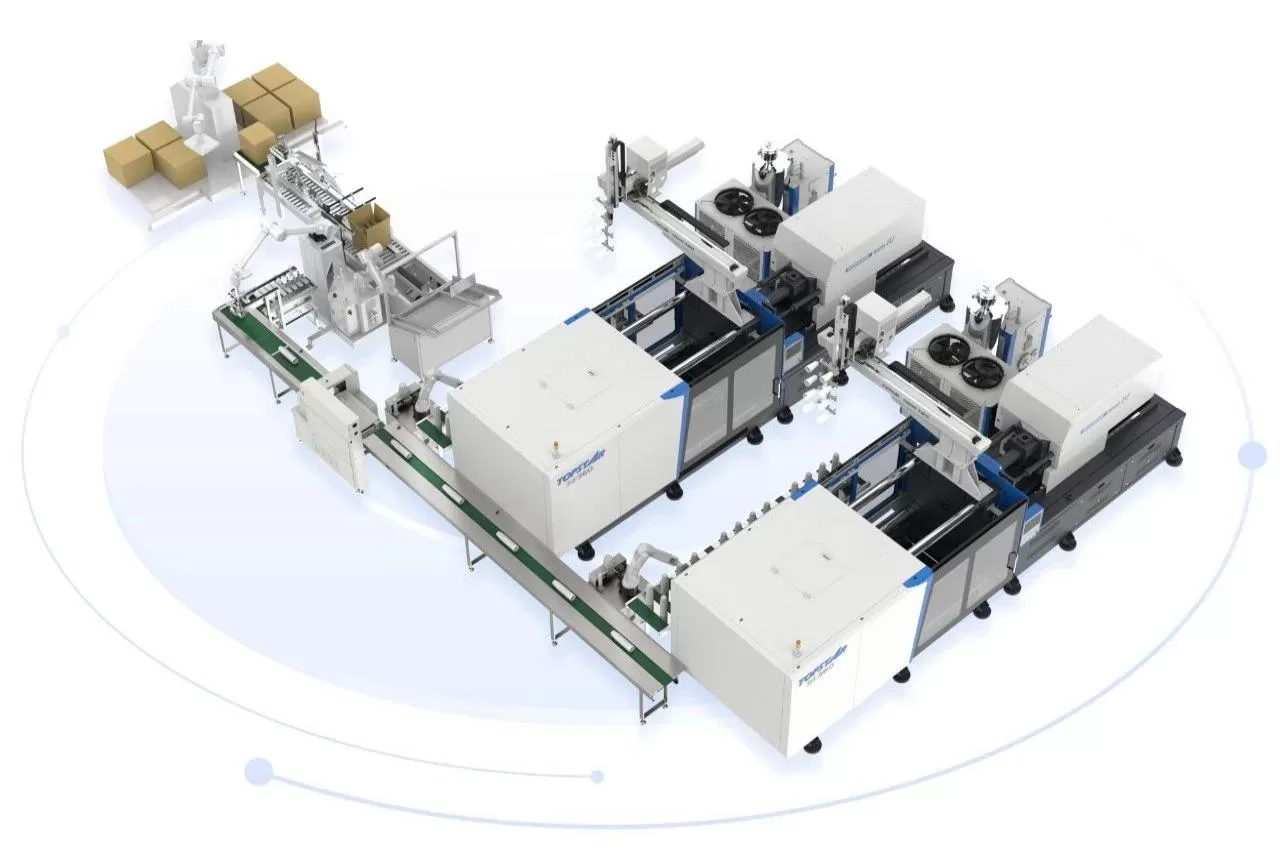

Leading one-stop injection molding machine solution

Topstar’s one-stop injection molding solution integrates multiple processes such as injection molding, material stacking, bagging and packaging, labeling, unpacking and boxing, sealing, and intelligent palletizing workstations into a cohesive production system. The system’s core is to use advanced automation technology, especially the automatic adjustment of the injection molding robot trajectory, to ensure continuous production. By… Continue reading Leading one-stop injection molding machine solution

-

2025/03/28 By: Topstar

How to achieve rapid response and stable temperature control of mould temperature controller?

In industrial manufacturing, the performance of the mould temperature controller directly affects production efficiency and product quality. Two key indicators determine its effectiveness: speed (how quickly it reaches the target temperature) and accuracy (how accurately it maintains that temperature). Slow response times delay production cycles, while unstable temperatures can lead to defects such as inconsistent… Continue reading How to achieve rapid response and stable temperature control of mould temperature controller?

-

2025/03/26 By: Topstar

Intelligent Injection Molding in Indian Factories with Injection Mold Machines

The Indian plastics manufacturing industry is experiencing unprecedented growth, driven by growing demand from the automotive, packaging and consumer goods industries. However, this rapid expansion is constrained by a significant technological gap in India’s injection molding capabilities. Today, the global manufacturing industry is implementing Industry 4.0 solutions through connected smart factories, but currently, about 75%… Continue reading Intelligent Injection Molding in Indian Factories with Injection Mold Machines

-

2025/03/24 By: Topstar

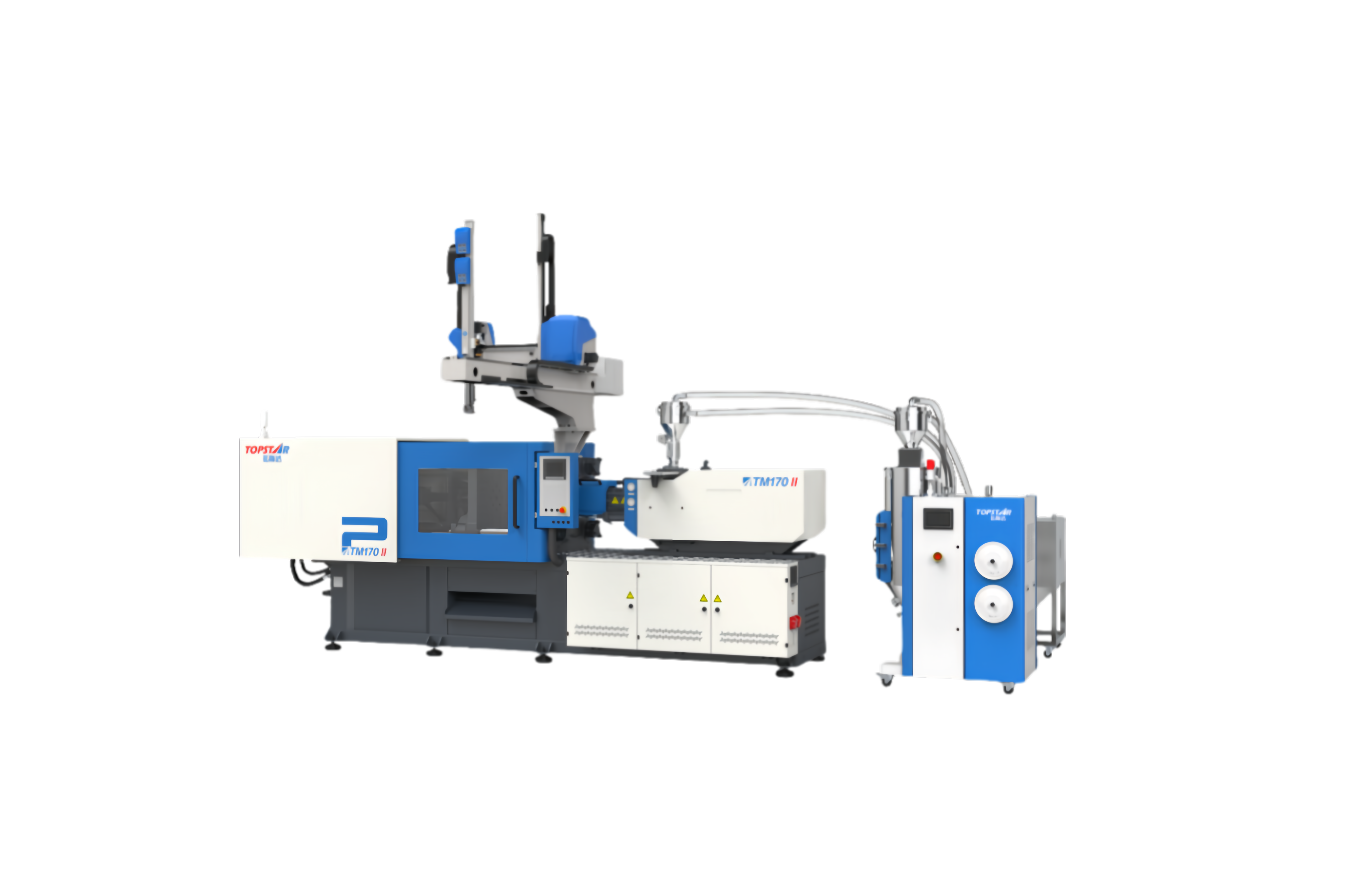

Intelligently adjust the power distribution of plastic injection molding machines

Integrating servo motor technology with plastic injection molding machines brings operational benefits beyond energy savings. One of the main benefits is enhanced control over the injection molding process. Intelligent power distribution allows operators to access real-time data and precise adjustments, promoting a more stable and predictable production environment. This level of smart control is very… Continue reading Intelligently adjust the power distribution of plastic injection molding machines

-

2025/03/21 By: Topstar

How to choose a chiller according to the actual injection molding situation?

Chillers can remove excess heat from the injection molding system, ensuring the mold and material maintain optimal processing conditions. For injection molding production, the decision of the chiller is not only about cooking but also about ensuring the stability of the entire manufacturing process. An efficient chiller system can prevent common problems caused by thermal… Continue reading How to choose a chiller according to the actual injection molding situation?

-

2025/03/19 By: Topstar

How to Solve Uneven Drying in Injection Molding with a Dehumidifying Dryer?

When processing engineering plastics, uneven drying can lead to defects, compromised structural integrity, and inconsistent final product performance. Traditional drying methods often rely on ambient heat or simple forced ventilation systems that do not provide consistent results, especially when processing complex engineering plastics. Variations in moisture content and temperature fluctuations can lead to uneven drying,… Continue reading How to Solve Uneven Drying in Injection Molding with a Dehumidifying Dryer?