Can large injection molding machine better grasp accuracy?

2023/12/04 By Topstar

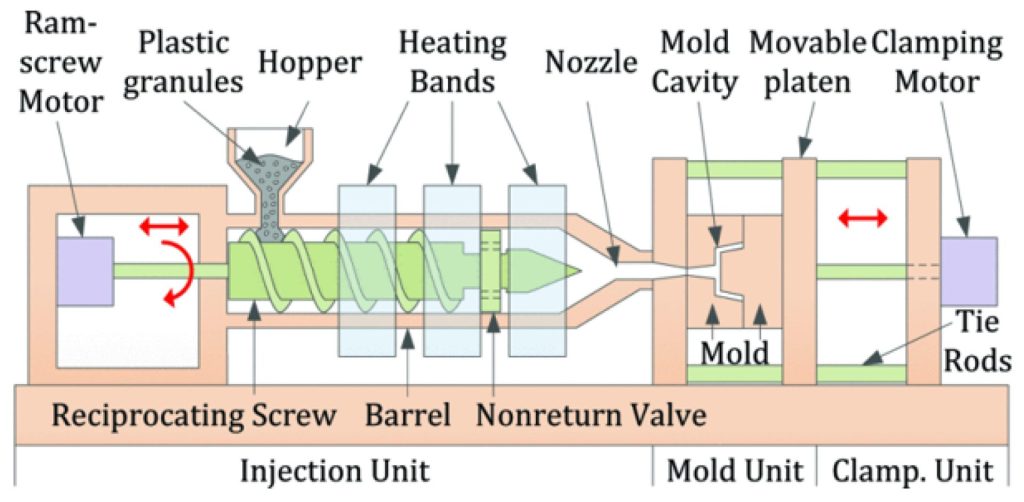

Whether a large injection molding machine or a small-scale injection molding machine, it is an essential part of the plastic manufacturing industry. Large-scale injection molding machines can produce large-scale molds to maintain grasping accuracy during large-scale production. The following article will educate you on whether large-scale injection molding machines can obtain high-precision gripping.

The basis for controlling the accuracy of large injection molding machine

The cornerstone of the accuracy of large injection molding machines lies in their complex design and engineering. These machines are characterized by robust controls and cutting-edge technology, allowing for high precision at multiple stages of the molding process. From meticulous material dosing to controlled injection and precise mold closing, every aspect of the operation is carefully planned. This section looks more in-depth at how large injection molding machines embody accuracy in their essential functions, laying the foundation for unparalleled precision in component manufacturing.

Progress in improving the precision of large injection molding machine

The combination of large injection molding machines and the most advanced servo drive system can significantly change the accuracy of large injection molding machines. These advanced systems precisely control the injection and clamping processes, allowing for finer adjustments and reduced variations in molded parts. The result is improved dimensional accuracy and improved overall product quality. In addition, integrating innovative technology and Industry 4.0 solutions pushes precision to new heights. Real-time monitoring and data analysis allow for immediate adjustments, optimization of process parameters, and minimization of deviations. Predictive maintenance based on data analytics ensures continued machine reliability and accuracy.

The influence of materials on the accuracy of large injection molding machines

Material selection in large injection molding machines can significantly affect accuracy, and high-performance materials with excellent dimensional stability and heat resistance are preferred for molds. These materials maintain their shape and properties under varying temperature and pressure conditions, helping to achieve precise molding results over extended production cycles. Engineering thermoplastics with specific mechanical properties and materials with low shrinkage and excellent flow characteristics ensure that molded parts maintain tight tolerances and consistent dimensions. Choosing the right, innovative material technologies can improve durability and wear resistance. This durability is essential for molds and features subject to heavy use and high-stress conditions.

Better strategies to improve accuracy

If you want to improve the accuracy of large injection molding machines, you also need to adopt predictive maintenance based on data analysis. This proactive approach ensures machine reliability, prevents downtime, and maintains accuracy by resolving potential issues before they impact production. Another uses CAD and CAM software for complex mold design and precise tool paths. This integration optimizes the entire molding process and also helps improve accuracy.

Overcoming Accuracy Barriers on Large Injection Molding Machines

Although they have excellent accuracy, they are not immune to common problems and obstacles. Regular calibration and maintenance of your injection molding machine will address wear and tear issues, ensure components function during operation, and aid in accurate molding. An advanced temperature control system manages thermal changes during the molding process. Stabilize mold and material temperatures. Of course, injection speed, pressure, and other parameters must also be fine-tuned for each molding application. Optimizing these settings reduces the risk of dimensional variation in molded parts and improves overall accuracy.

Pursue more precise precision

The above article shows that large injection molding machines can achieve precise accuracy. In the implementation process, we also need to perfect them, maintain and ensure each production process to ensure exact injection molding. machine.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/12/04

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/12/04

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/12/04

- Topstar Special | National Science and Technology Workers Day 2023/12/04

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC