Why Go With The Great Feeding And Conveying System?

2023/05/06 By Topstar

The feeding and conveying system is one of the most important components of every machine. Part of any manufacturing process transports materials while keeping them in the correct position. It is a system that aids in transferring materials into a manufacturing process. This means that there will be no spillage or waste while using this device. Since it keeps your product running smoothly, you can rest assured that nothing will go wrong.

The feeder and conveying system is one of the most important components in every machine!

Feeders and conveying systems are among the most critical components of every machine. It helps keep the material flowing and efficiently used and finished efficiently, keeping the product in the correct position for further processing.

It is a system that facilitates the transfer of material into the manufacturing process; it ensures no jams or stoppages during production or when transporting goods in a factory environment, thereby increasing productivity.

This system also helps keep your materials running smoothly!

It makes smooth use of your material. Feed and conveyor systems are a great way to get products in the right place. It also helps save time and money and ensures no material is wasted.

It features automatic speed control, which lets you adjust how fast or slow you move along the path at any time. Lastly, this machine has safety features, so it will shut itself off in case of a breakdown!

Feeding and conveying systems get the job done efficiently!

It makes the cutting or drilling process smooth and efficient when you use the feeding and conveying system. This system ensures that the material remains in place for further processing. It also helps to make your material work smoothly. There is no need for additional labor when handling different tasks in an industrial environment, all done by robots and automation.

The great thing about these machines is that they’re easy enough for anyone with basic mechanical knowledge to operate them without any issues whatsoever!

Feeding and conveying systems keep the product in the correct position.

Feed and conveyor systems are machine components that use automated methods to transport materials and bulk materials and are also suitable for transporting small workpieces during manufacturing.

The purpose of this system is twofold: First, it helps to keep the product in the correct position for further processing. Second, it allows the cutting or drilling process to be done smoothly and efficiently. Apart from that, it also keeps the material in smooth use so as not to cause any damage while transferring the material in the manufacturing plant.

It is a system that aids in transferring materials into a manufacturing process.

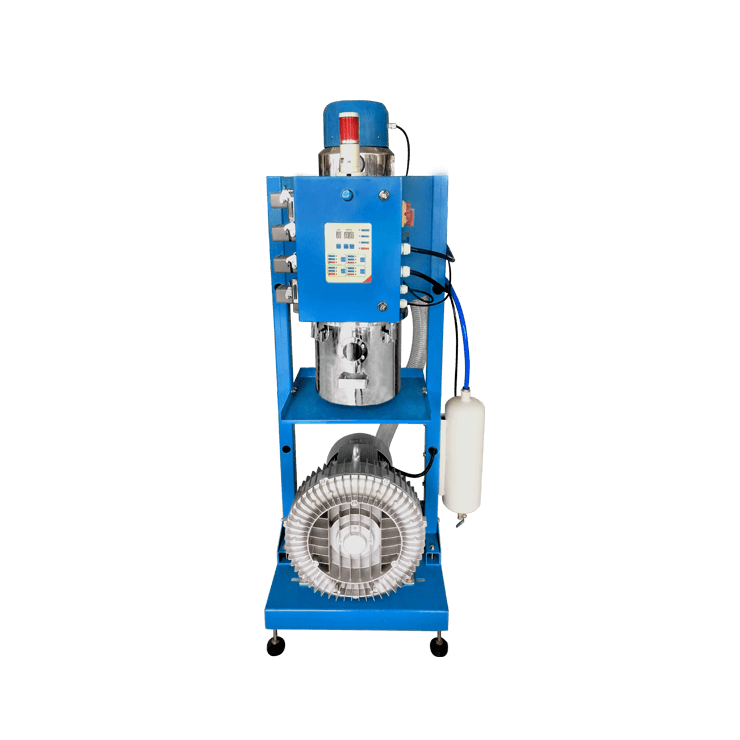

The Great Feeding And Conveying System is a system that aids in transferring materials into a manufacturing process. It moves materials from one place to another, from one step of a strategy to another, and even from one process to another. GFCS consists of several parts:

Feeder – An automated device that dispenses material at predetermined intervals or rates onto transport conveyors or machinery such as rollers or screw feeders.

Roller Conveyor – A device that moves product along its length using rollers mounted on an endless belt (usually rubber-covered steel). These typically move products within a specified time through packaging machines or other automated systems that require speed and accuracy. The screw conveyor is a spiral surface driven by a motor installed below and conveys solid granular materials through the hopper to the dustbin above. Simultaneously, gravity discharges onto trucks waiting below each discharge point. The bucket elevator is equipped with a bucket surrounded by holes of different sizes, which allow smaller particles to pass through and block larger particles.

Final

Excellent feeding and conveying system will help you get the job done conveniently. Through the above description, you also know why you choose it. Of course, these reasons are part of it. If you want to know more, you can browse and leave a message on our website.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/05/06

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/05/06

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/05/06

- Topstar Special | National Science and Technology Workers Day 2023/05/06

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC