Several things to know before purchasing CNC machine tools

2023/03/14 By Topstar

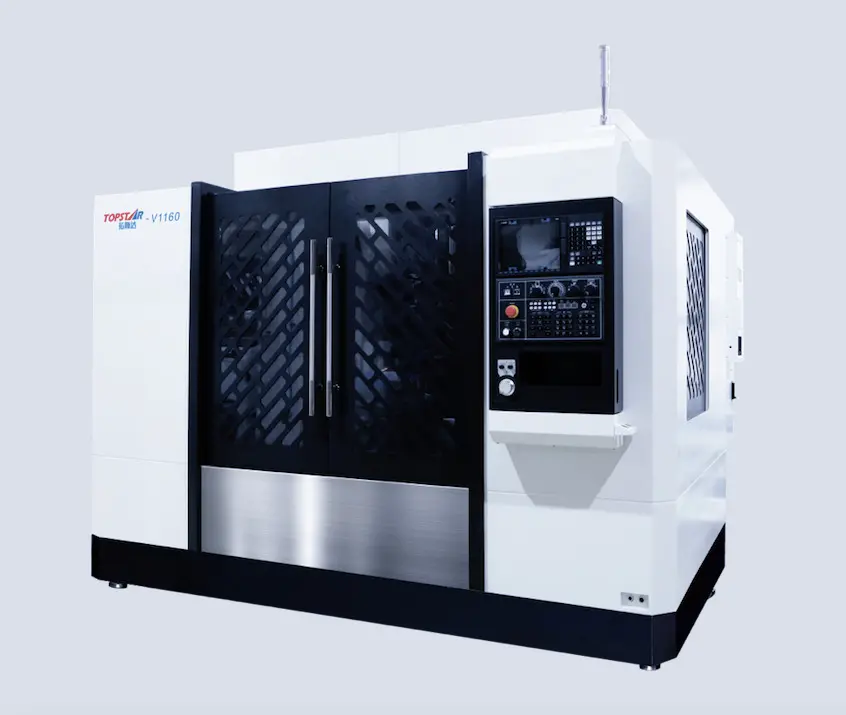

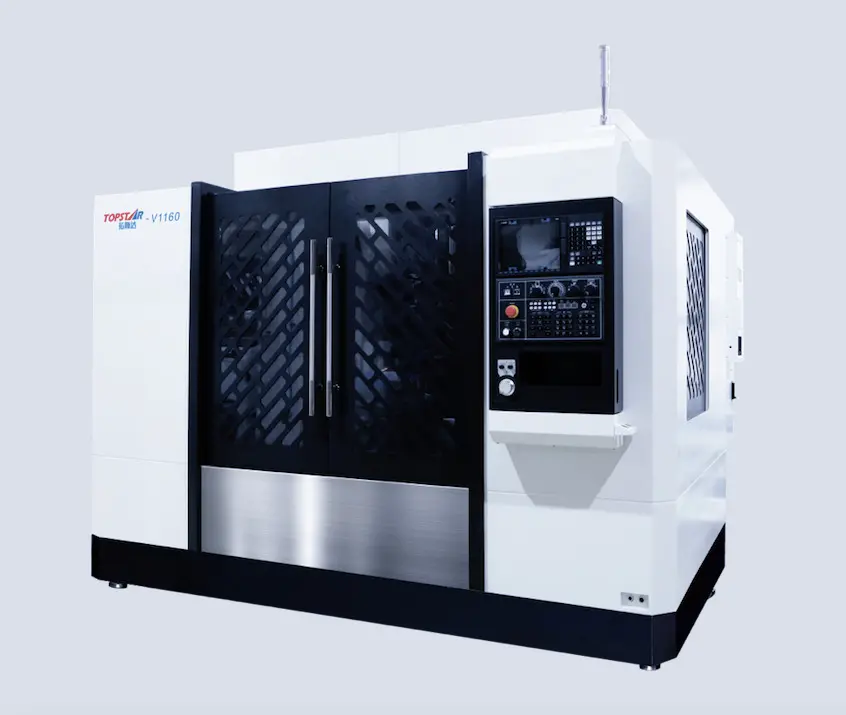

Purchasing CNC machine tools

If you’re interested in buying CNC machine tools, you’ve probably already heard about what they can do for you and your business. But before making a purchase, it’s essential to know precisely what CNC stands for and how much money you’ll need to make this investment worthwhile. To help with that process, we’ve put together some guidelines for purchasing CNC machines so that when the time comes for you to buy one of these fantastic machines, there won’t be any surprises waiting in the wings!

What is a CNC Machine Tool?

A CNC machine is a computer-controlled cutting tool designed to perform drilling, milling, and turning tasks. CNC is “computer numerical control,” which refers to how these machines operate. The computer uses special software programs to send instructions that tell the machine what to do and when to do it so that it can perform complex functions without human intervention.

CNC machines offer many benefits over traditional manual tools like saws or drills: they can be programmed with specific instructions for each task. They’re more accurate than handwork. And they’re faster than manual methods because there’s no need for human intervention during operation.

Many CNC machine tools are available today, some of which are designed for industrial use. Which type is best for your needs will largely depend on budget constraints and personal preferences, so take the time to research before buying!

Why Buy a CNC Machine Tool?

CNC machines are the way to go if you’re looking to start a business and need the best tools available. They make custom parts that would be difficult to make by hand, making them ideal for small businesses and startups if you want to put your company logo on everything from T-shirts to coffee mugs. Custom products will help get your name out there–and if you use a CNC machine for this purpose, people will notice!

CNC machines are also great for personal use: if something specific needs to be done around the house or garage. Purchasing one will save time and effort compared to using power tools that require manual labor.

The Difference Between Desktop and Portable CNC Machines

When shopping for a CNC machine, it’s essential to consider the difference between desktop and portable machines.

Desktop models are more significant and less portable than portable ones. They are easy to move but need more space in the workshop or garage. The larger size also means that desktop models are more potent than portables.

Portable CNC machines are smaller and lighter than desktops. They’re easier to carry from one place in your home or office to another without requiring much effort. But this comes at a cost: portables tend to cost more than their bigger counterparts because they don’t offer as much power as their bulkier counterparts. Still, if you plan on using the same workspace every day, purchasing an affordable desktop model may make sense over buying a pricier portable one, just so long as it meets all your needs!

What to Look For in a CNC Machine Tool

When you’re shopping for CNC machine tools, there are a few things to keep in mind. First, ensure that your chosen tool’s size and weight fit into your workspace. You also want the build quality of any potential purchase to be top-notch–this means it should have solid bearings and other components that aren’t prone to failure. Finally, consider features like onboard WiFi connections or touchscreens (if applicable).

Plan carefully before making your purchase.

Before you buy, consider the size and weight of the machine. If it’s too big, it might not fit in your workshop. Also, consider how much you will use it: If you plan on using it once or twice a year, maybe getting smaller is better because they are cheaper.

Once you’ve decided on a model and manufacturer, consider the space available for your new purchase. You want to ensure enough room for everything from assembly/disassembly to storage when not in use so that nothing gets damaged by being moved around too often.

Next thing: power requirements! This will vary depending on what kind of CNC milling machine tooling setup works best for whatever project(s) at hand. However, generally speaking, most modern models require between 5kW – 15kW worth of electricity just to run correctly. This means enough juice flows through these motors before anything happens. Believe me, when I tell you this last part is essential because if it is not done correctly. Things may crash soon after starting again later… So don’t forget these voltage requirements!

Final

The above points let you understand what you need to know and what to prepare before purchasing CNC machine tools. If you are still not sure whether to source it, we recommend that you take some time to consider your needs and the type of project you would benefit from. If you have any questions, you can continue to pay attention to our Topstar official website.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/03/14

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/03/14

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/03/14

- Topstar Special | National Science and Technology Workers Day 2023/03/14

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC