If you don’t understand the automation of injection molding robots, please read it!

2022/12/28 By Topstar

If you don’t understand the automation of injection molding robots, please read it!

Robots are widely used in modern production. The injection molding machine uses plastic particles as raw materials, fed into a hopper by an electric feeder. The plastic is heated to a melting point of 240~260 degrees Celsius in an extruder under high pressure and then injected into the mold cavity. The final melt process is cooled and solidified, forming a product. At this time, the robot hand takes out the effect from the mold on the conveyor belt for further processing.

Injection molding applications in various industrial sectors

Injection molding is widely used in a variety of industries. This is because it is one of the most efficient and cost-effective ways to produce plastic products.

In many instances, injection molding can be used to make all the parts needed for a product. Suppose a position requires more than one material or color. In that case, it makes sense to use an injection molding process since this type of manufacturing allows for multiple fabrics and colors per part. In addition, injection molding provides greater precision than other processes, such as extrusion or blow molding. This will enable you to create pieces with detailed features that would be difficult or impossible using different processes.

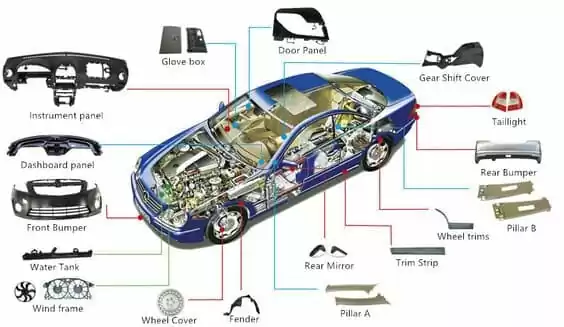

Since so many industries rely on plastic components, many different types of products could be made using the injection molding process: automotive parts, medical devices, and equipment; consumer goods such as toys; building materials such as siding; sporting goods like golf clubs; industrial equipment like gears and bearings…the list goes on!

The injection molding machine operates in the following manner.

The injection molding machine operates in the following manner: first, the plastic particles are fed into the molding machine and then heated and compressed. The plastic particles melt due to thermal energy, forming a soft or viscous state. The mold cavity is filled with this melted material. Under pressure, the fluid flow path is formed. When an external force is released, it will harden again after cooling to room temperature.

Plastic particles under high-pressure melt

Injection molding is mainly used in plastic products. The primary injection molding process is to melt plastic particles under high pressure. After injection into the cavity of the product mold, cooling and solidification will form plastic products.

The robot hand takes the product from the mold.

At this time, the robot hand removes the product from the mold and puts it on the conveyor belt for the following process. The robot hand is made of high-strength aluminum alloy, which can be rotated freely to pick up and place products with high accuracy. It’s simple to use; you must put it in the line direction according to instructions from CAD drawing or software system design.

The robot hand is suitable for pick-and-place operation in electronic and mechanical industries. It can be used to pick up and place small parts, such as IC, LED sheet, etc. The robot hand has two fingers and one thumb that are complex copper electrodes. They can easily pick up the products with high accuracy by electrostatic force.

Unlike ordinary injection molding machines

Unlike ordinary injection molding machines, the most critical parts of robots are robotic hands. They remove the mold and place the product on the conveyor belt. Transport it to another place or perform other tasks. We should know about this because it can help us understand how automation works.

The second thing we need to understand is that many different robotic hands are available today, which means they all have additional features and specifications. Therefore, before buying a machine that uses this technology in the design process. It would be best if you made sure that you first investigate all available options to avoid wasting money (or worse) on unnecessary things. Buy products that do not entirely meet your needs!

Robots are widely used in modern production!

Robots are suitable for modern production. They mainly play a role in manufacturing, assembling, and testing products. Robots also play an essential role in packaging products.

As time passes, the application of robots in the manufacturing industry has increased. Many industries are using this technology, which helps to improve productivity and reduce production costs.

To sum up-automation of injection molding robots

The injection molding machine represents modern production equipment, and the Robot is also an auxiliary device. This way, the injection molding robot is more efficient and accurate than ordinary machines.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/12/28

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/12/28

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/12/28

- Topstar Special | National Science and Technology Workers Day 2022/12/28

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC