Home / What is injection robot arm

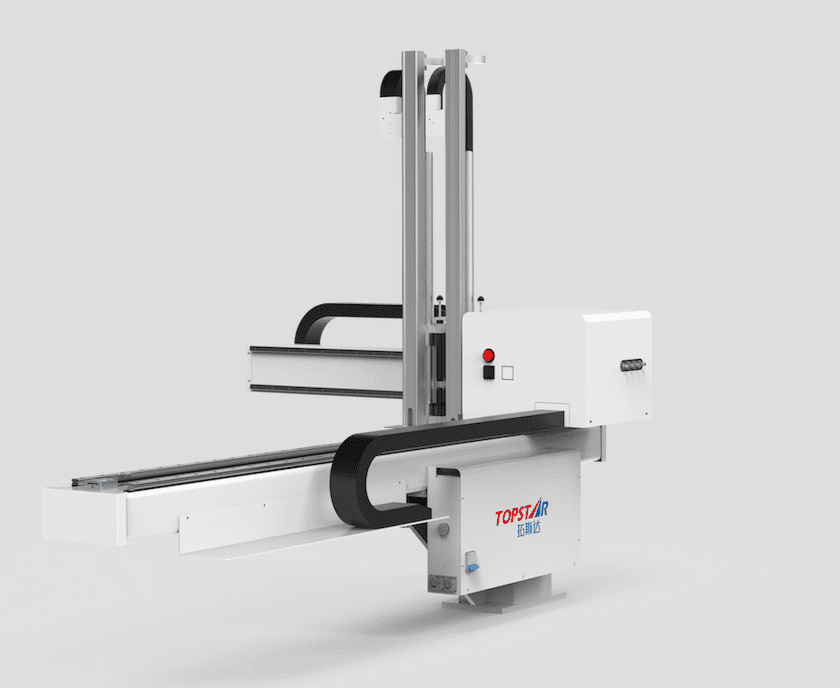

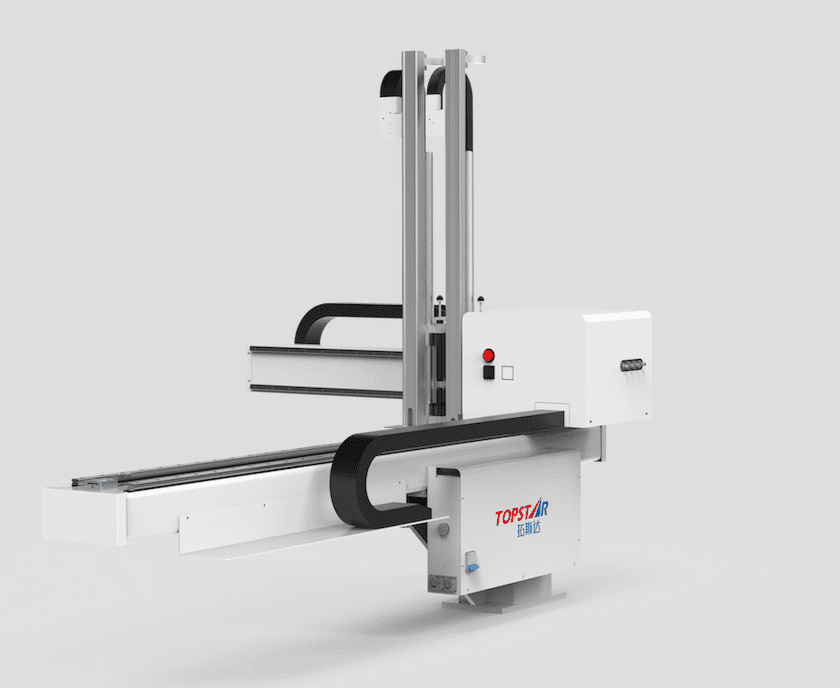

Injection robot arm

Robots are becoming increasingly common in manufacturing warehouses as companies look to automate their processes. The benefits of this are clear—it saves companies money and time while also improving quality by removing human error from the equation. But what exactly is an Injection robot arm? This article will dive deeply into what these bots do and how they work to make your manufacturing process more efficient.

An Injection robot arm is an industrial robot.

An injection robot arm, also known as an automatic machine tool, is an industrial robot. It performs a series of repeated actions on the injection molding machine. To make the process faster, more consistent, and more accurate.

These robots are used to mass-produce parts with small or complex geometric dimensions. It is difficult for humans to assemble by hand. They can also be programmed to perform tasks with increased accuracy over time.

An important application is to take parts out of the mold during production.

Injection molding robots are used to remove parts from molds during production.

The robot arm must be specially designed to protect the electrical components inside from heat and damage.

The material used in molding is also very tough. So the end effector or gripper on the robot needs to be robust enough to handle it without breaking or falling apart.

This can be a tricky task since the molds are extremely hot.

Injection molding is a process that injects molten plastic into a mold, where it cools and hardens. The molds are usually made of metal but can also be made from wood or other materials. This can be a tricky task since the molds are extremely hot. They need to be heated up to melt the plastic to fill them. However, if they get too hot, they risk damaging themselves or burning someone working with them!

To prevent this, manufacturers have special tools that allow them to measure and control the temperature of their molds. These tools come in various shapes and sizes depending on what type of plastic is used and how hot it needs to be.

The robot arm must be specially designed to protect the electrical components inside from heat and damage.

Injection molding robots need to be designed with the operator in mind. This means they must be easy to use and allow the operator to make changes on the fly. Many people use industrial robots to meet their injection molding needs because they can seamlessly integrate into existing production lines and reduce costs.

To learn more about using industrial robots for your business, visit https://www.topstarmachine.com.

The material used in molding is also very tough.

When you’re working with very tough materials, it’s essential that the end effector or gripper on your robot can handle the material without breaking. For example, if you’re using a material made of hardened steel and your end effector is made of plastic. Then that would be a recipe for disaster! The materials used for forming are also very tough, so the end effectors or clamps on the robot must be strong enough. To be treated without fracture or separation and able to withstand high temperatures.

Robots are entering the manufacturing space for injection molding

Injection robot arms are used in manufacturing plastic products due to their ability to perform repetitive tasks, precise and accurate movements, high strength, and endurance. Robots can also be used for dangerous or complex tasks that require a large amount of force.

Robotics development can be attributed to the need for more efficient ways of performing tasks in factories and other industrial environments. Robot arms are used in the automotive, plastics, and construction industries.

Last

We’ve covered a lot of ground here, from how robots work to how they fit into the injection molding process. It can be overwhelming to think about all the different pieces that go into making a robot, but hopefully, we can show you that with enough research and hard work, anyone can build their custom machine! It takes time and patience, but we believe it will be worth it when your creation is up and running alongside its human counterparts in factories worldwide.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/12/18

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/12/18

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/12/18

- Topstar Special | National Science and Technology Workers Day 2022/12/18

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

Afrikaans

Afrikaans Albanian

Albanian Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) English

English French

French Portuguese

Portuguese Russian

Russian Spanish

Spanish Turkish

Turkish