How to choose a Desktop Injection Molding Machine

2022/12/15 By Topstar

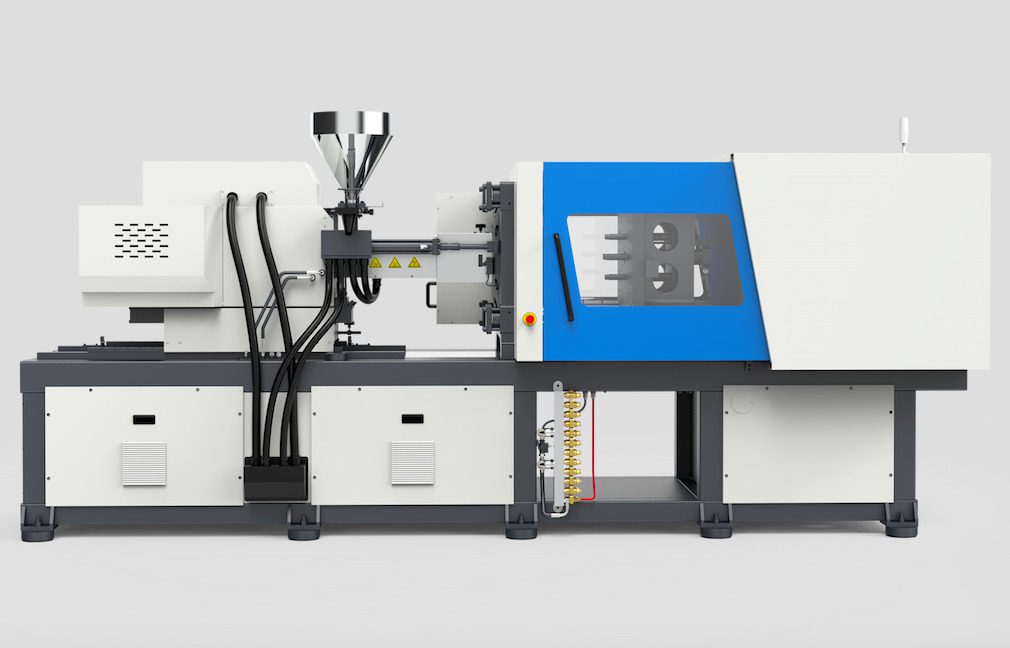

How to choose a Desktop Injection Molding Machine

A Desktop Injection Molding Machine is an excellent way to start injection molding. Desktop computers are more precise, compact, and easy to use. They can also be used for small-batch, prototype, and small-batch production. However, before you buy a desktop injection molding machine, you should remember a few things.

Consider the required injection volume

When choosing a bench injection molding machine, the required injection volume is the first to consider. If you are making small parts, a benchtop machine can be used. If you are making large parts, a full-size machine is required. And if you are making extensive parts, then a twin screw machine is needed.

The next thing to consider is the material you will be using. If you are working with plastics, you will need an injection molding machine that can handle many different types of plastics. For example, if you are making a plastic water bottle and need to inject polyethylene terephthalate (PET). Then you will need a machine that can handle this type of material.

Consider the clamping force

Another essential factor to consider is the clamping force. The clamping power is the amount of pressure the machine applies to your mold, which can significantly impact the quality of your finished product. If your clamping force is too low, you may have defects in your object, like air bubbles or undercuts. On the other hand, if it’s too high—or if there’s too much variation from one shot to another—it could damage your mold and reduce its lifespan.

The good news is that most desktop injection molders allow you to adjust this variable, so it’s just right for you!

Choose a machine with the best injection speed

The injection speed of the molding machine is a measure of how fast the device can inject material into a mold. The injection speed is determined by two factors: injection pressure and rate. The higher the injection speed, the higher productivity.

Choose a reliable machine

You should select a reliable machine. The machines should be able to run for many hours without breaking down. Have a good warranty, service network, and track record.

Finally, you should ensure that the machine is compatible with your computer system. You want to be able to use it with any operating system and software programs you already have on your computer.

It may affect productivity, product quality, and final profit

Choosing the suitable desktop injection molding machine will impact your productivity, product quality, and earnings. The two main types of desktop injection molding machines are:

Handheld – This is the handheld version of a large industrial machine that can run anywhere from $300 to $30,000. These machines are great for making small batches or prototypes, but they’re not meant for mass production. If you want to make ten or fewer parts regularly, this is an effective way to go about it without investing in an expensive machine. However, plan on making more than ten parts simultaneously (or even dozens). It might be worth investing in something more significant, like an automated unit that uses conveyor belts instead of human hands holding each part as it’s being injected with the material.

In the final analysis

There is no absolute answer to this question. Whether you choose a smaller desktop or our mainframe, please rest assured that we will provide you with the best machine. Welcome to our homepage to further understand the desktop injection molding machine products, and if you have any questions, please feel free to consult us.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/12/15

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/12/15

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/12/15

- Topstar Special | National Science and Technology Workers Day 2022/12/15

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC