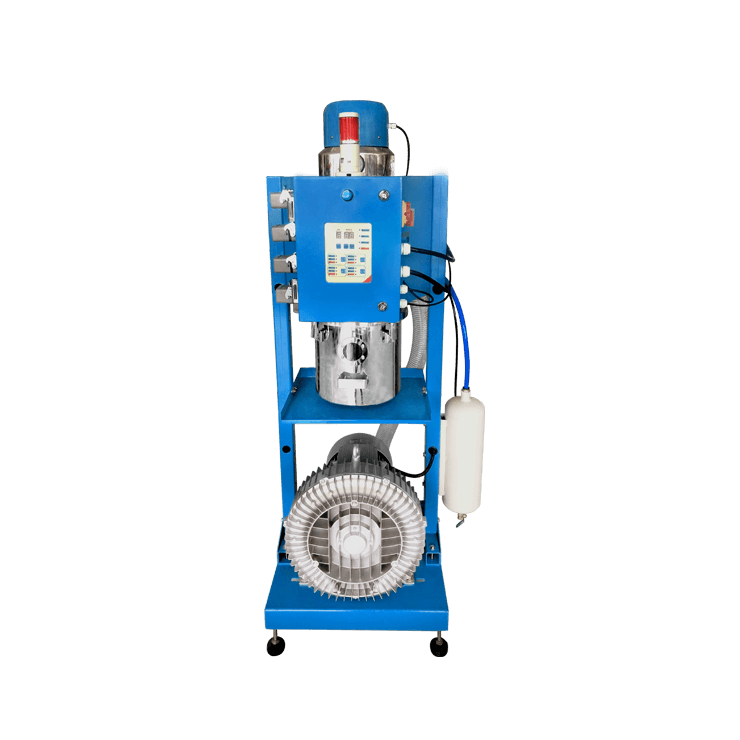

Feeding and Conveying System

Stainless steel (corrosion free) single hopper loader is designed to provide rapid transportation of free-flowing for virgin resin or regrind resin directly to the injection molding machine. The design of the hinged upper cover of the vacuum motor ensures quick cleanup time and easy maintenance.

Features

- 1. The main controllers and material hopper receivers are designed separately.

- 2. Can match 2 or above 2 hopper receivers to achieve one to multi combination conveying.

- 3. Material conveying capacities can be up to 700kgs/hr.

- 4. The maximum loading distance can be 10m, suitable for conveying materials over long distance.

Application Industries

- 1. Electronics

- 2. Containers

- 3. 3C home appliances

- 4. Cosmetics

- 5. Auto parts

- 6. FMCG

Adequate supply of goods, available for delivery within 35 days.

Description

What’s unique about the feeding and conveying system⇓

Topstar introduces an efficient and adaptable feeding and conveying system with cutting-edge technology. The central controller, employing advanced control technology, boasts robust data processing capabilities and flexible control logic. This enables precise monitoring and control of the material conveying process, ensuring a consistent and timely supply.

As an integral part of the system, the hopper receivers operate independently from the central controller. Configurable with multiple hopper receivers, the system facilitates simultaneous placement and supply of diverse materials. Each hopper receiver features an independent control system, allowing adjustment and control based on specific material requirements, guaranteeing accurate delivery.

The unique design and features of the feed conveyor system make it well-suited for modern production lines. Offering flexible pairing capabilities and a range of hopper receiver options, it accommodates diverse material supply needs. Furthermore, its scalable maximum loading distance ensures applicability to various sizes and layouts of production environments.