How to use Topstar injection molding machine to realize smart manufacturing technology?

2025/03/07 By Topstar

Intelligent manufacturing is the development trend of the manufacturing industry, and the cornerstone of Topstar’s smart manufacturing strategy is the concept of open injection molding machine control systems. Traditional injection molding machine usually operate as isolated units with limited interaction between components and minimal flexibility in adapting to different production requirements. At Topstar, we have redefined this model by developing a platform that integrates software and hardware to create a seamless, interconnected production environment. The system enables all aspects of the production process to work together harmoniously. The result is an optimized production line with real-time data exchange and dynamic adjustments that significantly improve overall efficiency and product consistency.

In addition, our system’s open architecture allows for continuous upgrading and customization. Manufacturers can easily customize the injection molding machine’s functions to meet specific needs, whether it is adjusting to produce high-precision parts or adapting to different raw material properties.

Improving production intelligence through open software control of injection molding machine

The core pillar of Topstar’s innovation is our open software control system, which can transform traditional injection molding machines into innovative, adaptable tools for modern manufacturing. The open system acts as the brain of the injection molding machine, connecting various production modules and facilitating seamless communication between them. With our injection molding machine technology, customers can fully customize process parameters to suit specific applications, ensuring consistent performance even under fluctuating conditions.

Our open software platform comprehensively controls key variables such as temperature, pressure, and cycle time. In addition, the open architecture of our control system allows manufacturers to integrate additional software modules and external devices. This includes connecting the injection molding machine with peripherals such as robotic arms to automate material handling or incorporating it with energy management systems to improve efficiency.

End-to-end intelligent injection molding production line

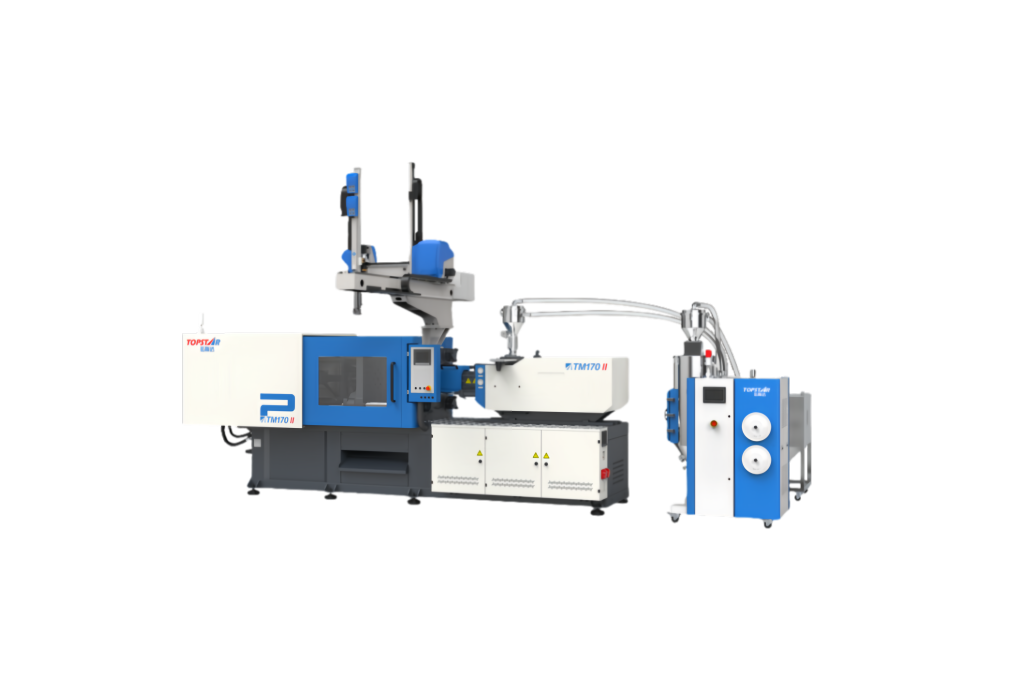

Smart manufacturing requires seamless integration across workflows. Topstar’s injection molding machines are synchronized with robotic part removal systems, conveyors, and vision inspection units through a unified control interface. For example, a US medical device producer has automated its entire production line from resin drying to packaging, reducing manual labor by 60%. The injection molding machine’s “plug and play” peripheral device connection ensures that auxiliary equipment such as chillers and dryers autonomously adjust settings based on real-time process data. This end-to-end automation shortens cycle times and reduces human errors, resulting in a 25% increase in overall equipment effectiveness. To further simplify operations, Topstar’s machines feature predictive maintenance. Sensors monitor key components such as hydraulic pumps and heaters, alerting operators to potential failures before they occur.

Customized injection molding machine solutions for specific industry applications

For example, Topstar can provide PET-specific injection molding machines to address the molding difficulties of PET raw materials. The unique machine uses a dedicated screw, a high-torque motor, and an enlarged power system to increase the overall plasticizing efficiency by more than 20%. At the same time, it also dramatically reduces defects such as bubbles and impurities that may occur during the molding process, ensuring the permeability and yield rate of the molded preforms. This industry-specific customization is supported by the open architecture control system, which allows seamless integration of additional modules and intelligent control functions. As a result, customers can improve the injection molding machine’s performance and adapt to changing market demands and technological advances.

Promote management informatization

Management informatization is another key aspect of our solution. By collecting detailed data on key production indicators such as cycle time, energy consumption, and product quality, the control system of the injection molding machine provides real-time insights, enabling manufacturers to make informed decisions. This data is accessible through a user-friendly dashboard, allowing production managers to monitor performance, identify bottlenecks, and implement process improvements promptly. Integrating this comprehensive data analysis into the production process is game-changing because it promotes continuous improvement and improves overall productivity.

In addition, the system supports seamless connectivity with other manufacturing equipment, including sensors, robotic arms, and central feeding systems. This connectivity ensures that all production line components operate coordinated, reducing delays and increasing production. The result is an intelligent, data-driven production environment that improves efficiency and provides consistent, high-quality output.

Realizing the vision of intelligent manufacturing

We perfectly combine advanced open software control with powerful hardware core technology, from feeding and molding automation to discharging automation and whole production line management. We fully integrate all aspects of the production process to ensure manufacturers achieve higher efficiency, better product quality, and lower operating costs. This intelligent integration capability enables our injection molding machines to communicate seamlessly with auxiliary equipment, promoting automation and comprehensive management informationization of the entire production line.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/03/07

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2025/03/07

- Star Case | Topstar helps Santong upgrade its intelligent plant 2025/03/07

- Topstar Special | National Science and Technology Workers Day 2025/03/07

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC