Bringing lower energy consumption injection molding machine solutions to Mexico

2025/02/19 By Topstar

Mexico’s manufacturing and injection molding industries have great potential, especially in sectors such as automotive, electronics, and consumer goods, especially in areas close to the US market. Of course, while facing the comprehensive upgrading of manufacturing, some regions of Mexico still face challenges such as unstable or insufficient power supply and a relative shortage of highly skilled workers. These problems may lead to inefficient production and increased operating costs. In order to help the Mexican manufacturing industry develop and progress better, Topstar established an office in Mexico in 2023 to help manufacturers overcome these challenges. By providing energy-saving, intelligent injection molding machine solutions, and after-sales training services, Topstar aims to improve the overall efficiency of Mexico’s manufacturing industry. This article will share how Topstar helps Mexican companies solve problems such as unstable power supply, lack of skilled labor, and the need for intelligent manufacturing solutions.

Solve power supply problems with an energy-saving injection molding machine

One of the most pressing challenges facing Mexico’s manufacturing industry is the unstable or insufficient power supply in some areas. Regions such as Guadalajara and Monterrey are essential manufacturing centers. Still, they also have dense populations and surges in electricity demand, which often experience power fluctuations, affecting production and increasing operating costs. These power problems may lead to equipment failures, production delays, and increased electricity bills, ultimately reducing the profitability of enterprises.

Topstar designs its injection molding machine solutions to address these power challenges by incorporating energy-saving technologies. Specifically, Topstar’s TE II electric injection molding machines feature intelligent servo motors and a self-developed control system that minimizes energy consumption while maintaining high performance. By optimizing the injection molding process, these machines use only the energy required for each specific operation, reducing power waste and improving overall energy efficiency. Compared to hydraulic injection molding machines, energy-saving injection molding machines like the TE II only consume electricity when needed, saving much energy. In areas with unstable power supply, this energy-saving solution not only helps mitigate the impact of power fluctuations but also reduces overall production costs.

Impact of skilled labor shortage in Mexico

Despite Mexico’s large labor force, there is often a shortage of highly skilled workers in specialized manufacturing fields such as injection molding. For many companies, this skills gap can lead to production inefficiencies, errors, and delays. Training and retaining skilled workers is essential to improving productivity and ensuring optimal machine operation.

In order to better enhance Mexico’s workforce, Topstar established an office in Mexico in 2023 to provide on-site training and technical support to local workers. Through this initiative, Topstar offers comprehensive training programs for operators, maintenance personnel, and engineers, focusing on the proper operation, maintenance, and troubleshooting of injection molding machines. This allows technicians to master Topstar’s injection molding machines through hands-on simulations, ensuring seamless adoption of IoT-enabled controls. This localized approach minimizes reliance on foreign experts and builds long-term technological autonomy. It equips its employees to handle the complexities of modern injection molding technology.

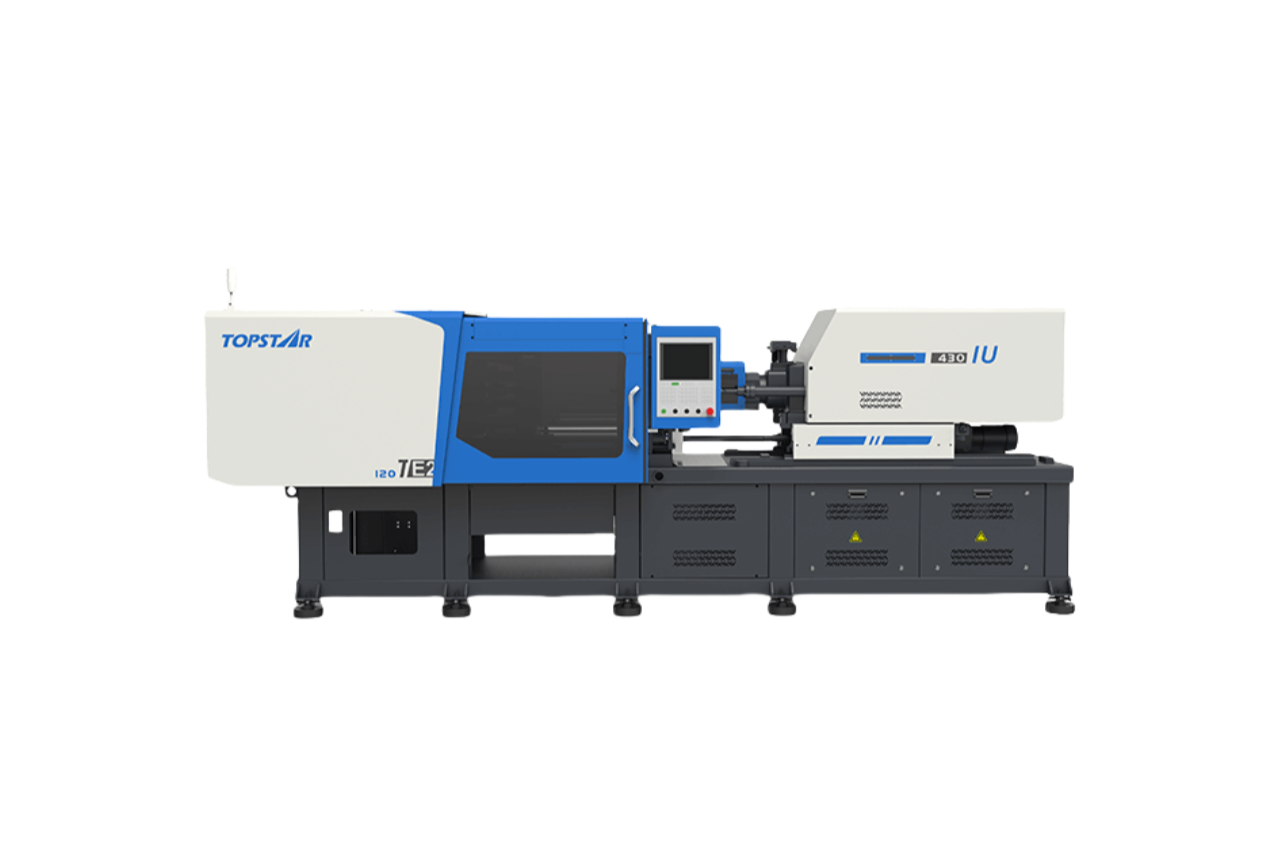

Topstar TE II Electric Injection Molding Machine: Features and Benefits for Mexican Manufacturers

One of the key features of Topstar’s TE II electric injection molding machine is its open, compatible, and upgradeable design, which makes it an ideal choice for Mexican manufacturers looking to integrate innovative technology into their production lines.

The TE II injection molding machine is equipped with a discrete intelligent drive control system that reduces communication delays and ensures real-time control of servo motors. This significantly improves the accuracy of position, speed, and pressure control, allowing manufacturers to produce high-quality parts with greater consistency and precision. By increasing the response speed by 8-16 times, TE II machines provide a more efficient and stable molding process, helping to minimize energy consumption by 40-60% and improve overall productivity. Despite frequent voltage fluctuations of 10%, the technology still reduced the scrap rate by about 22%. In addition, designers can also design them to handle a variety of materials and applications, meeting the flexibility required for the specific needs of different production lines.

Key to improving efficiency and reducing energy consumption

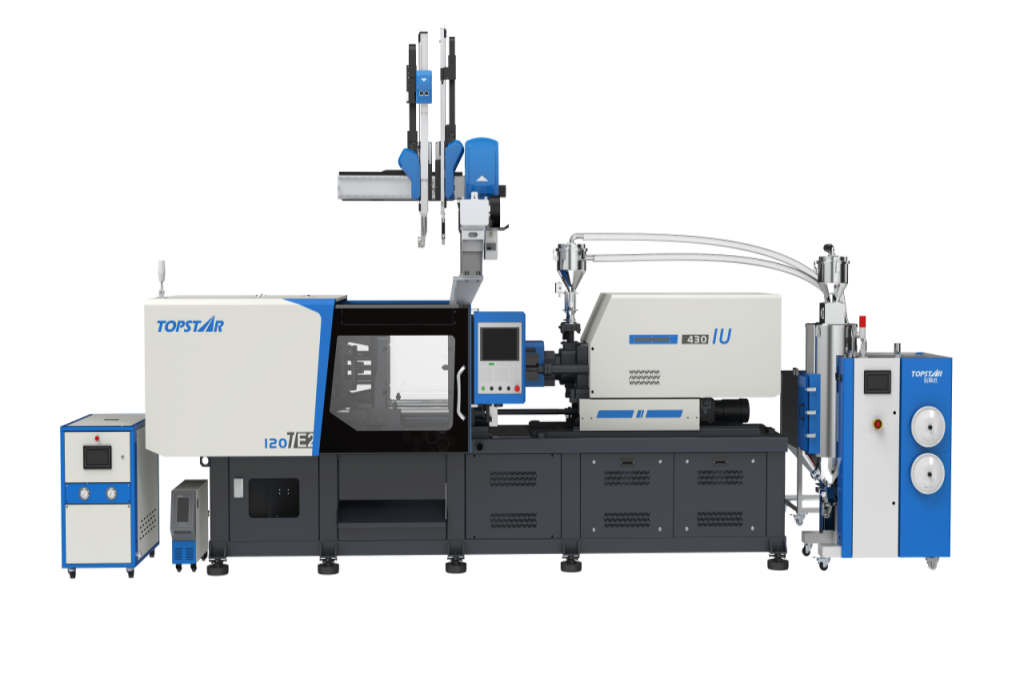

The integration of the injection molding process is another key factor in achieving reduced energy consumption and improved efficiency. Among the injection molding machines produced by Topstar, the concept of “injection molding process integration” is adopted. This holistic approach allows better communication between the different stages of the molding process, ensuring that each step uses energy efficiently. By combining injection molding with intelligent automation systems such as central feeding systems and injection molding robots, auxiliary equipment, etc., Topstar’s injection molding machines help reduce dependence on manual labor, improve precision, and increase production speed. The integration of these technologies not only reduces energy consumption but also enhances the overall quality of molded products, reduces the risk of defects, and minimizes waste.

Solving Mexico’s Factory Building Infrastructure Challenges

In addition to providing advanced injection molding machine solutions, Topstar can also provide injection molding factory solutions, offering complete modular planning and construction services. One of the challenges facing Mexican manufacturers is inadequate infrastructure, especially in newer industrial areas or areas with less developed manufacturing facilities. In this case, factory construction and equipment installation can be time-consuming and costly.

Topstar solves these infrastructure challenges by providing a one-stop modular planning service. This includes the integration of injection molding machines, auxiliary equipment, front-end automation systems, and back-end robotic automation modules, all of which work seamlessly together to increase productivity and reduce operating costs. By taking a modular approach, manufacturers are able to quickly build fully functional production lines to meet their specific needs. This modular solution not only saves time and resources but also ensures that the factory is designed with scalability in mind.

1-1024x682.webp)

Bringing more imaginative injection molding solutions

As Mexico gradually develops into a manufacturing hub, the demand for high-quality, energy-efficient injection molding solutions will only increase. With Topstar’s innovative injection molding machine solutions, Mexican manufacturers are well-positioned to meet this demand and address challenges such as unstable power supply, labor shortages, and infrastructure gaps in various regions. Topstar’s commitment to innovation and local support ensures that better overseas manufacturers can rely on cutting-edge technology and expert guidance to optimize their operations.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/02/19

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2025/02/19

- Star Case | Topstar helps Santong upgrade its intelligent plant 2025/02/19

- Topstar Special | National Science and Technology Workers Day 2025/02/19

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC