Using Topstar’s plastic injection molding machines to solve production problems for Indian users

2025/02/17 By Topstar

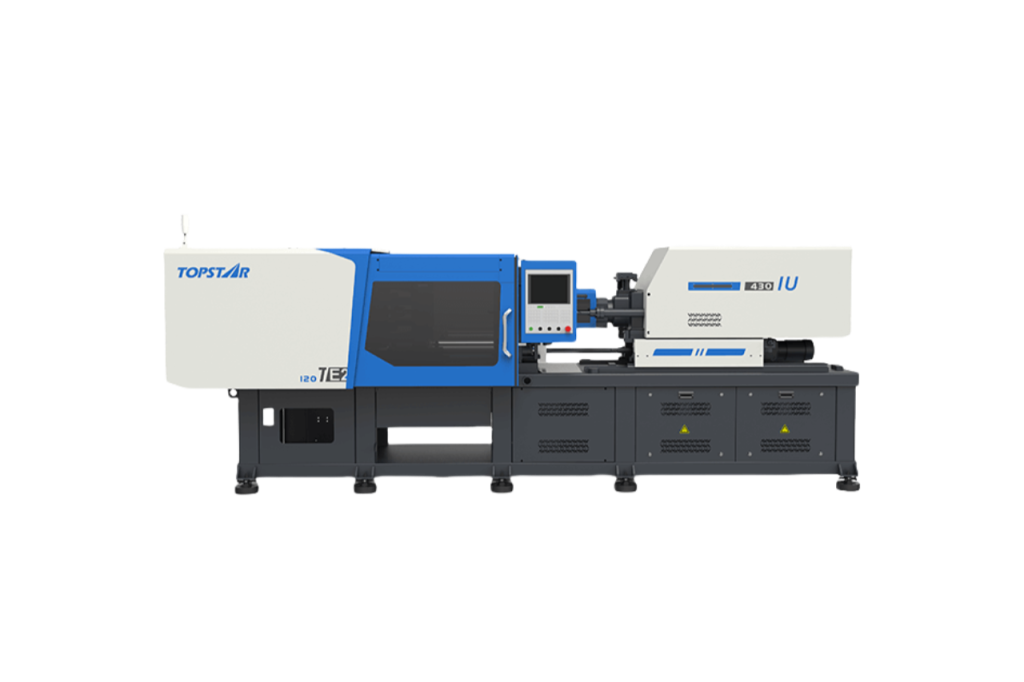

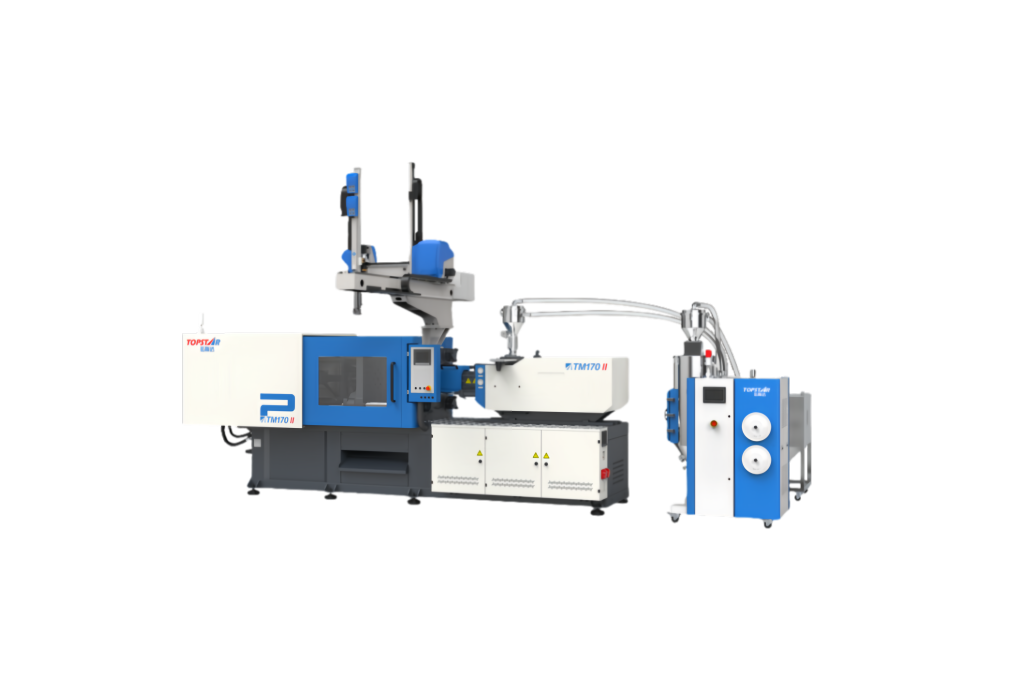

India is one of the fastest-growing economies in the world, and its strong market demand for plastic products has also attracted the attention and participation of many global plastic machinery companies. At the same time, for many Indian plastic product manufacturers, production still faces problems such as unstable regional voltage, high demand for energy-saving Injection molding machine solutions, the upgrading of the entire Indian manufacturing industry, and the growing demand for automation. In Topstar’s plastic injection molding machines, by leveraging the features of the TE II series electric injection molding machine and the TM II series injection molding machine, Indian manufacturers can enjoy stable product molding, faster production speeds, higher energy efficiency, and comprehensive technical support tailored to local needs.

Solve the problem of unstable voltage in India with plastic injection molding machines

One of the main challenges faced by Indian plastic product manufacturers is the problem of unstable voltage in certain regions. A fluctuating power supply not only disrupts the production cycle but also affects the quality and consistency of the final molded product. Topstar designs its plastic injection molding machines, especially the TE II series, to operate efficiently under such conditions. They use advanced electronic components and voltage control systems to ensure a stable injection molding process even when the power supply is unstable.

The high rigidity structure of the injection unit in these machines plays a vital role in maintaining consistent pressure and temperature during the molding process. Problems such as warping or incomplete filling that occur when the voltage of plastic injection molding machines drops can be prevented, resulting in a yield of more than 95% – significantly higher than the typical yield of 80% expected by many manufacturers. In addition, energy-saving features are designed to help eliminate power fluctuations and reduce the risk of overheating and other problems that may occur due to inconsistent energy input.

Maximize energy efficiency and create a cleaner workshop environment

In a market where energy costs are rising, energy efficiency is a key factor for manufacturers. In particular, the comprehensive upgrade of automated manufacturing in India has put production facilities under tremendous pressure to minimize energy consumption while maintaining high output. Topstar designs its plastic injection molding machines with energy-saving and environmental protection in mind. Our TE II electric injection molding machines use discrete intelligent drive control, which has a fast motion response and can improve energy efficiency by 20%. This control method enables our machines to reduce power consumption while providing consistent and high-quality results significantly. At the same time, their clean operation creates a safer and more organized workshop environment—a benefit that particularly supports safety in India’s densely populated industrial areas.

Improve the automation of plastic injection molding machines

With the rapid modernization of India’s manufacturing industry, the demand for automation has grown exponentially. Many manufacturers are increasingly looking for solutions that can not only increase production speeds but also reduce reliance on human intervention. Whether it is the TE II series or the TM II series plastic injection molding machine, manufacturers equip it with a full set of independently developed injection molding equipment, enabling data interconnection between equipment systems. This data interconnection facilitates real-time monitoring and control, allowing operators to make quick adjustments without interrupting the production process. It also allows them to efficiently manage the system quickly, thereby reducing the need for professional training and minimizing downtime.

Of course, this automation function also extends to the entire molding process, from precise control of injection speed, pressure, and melt flow to automatic adjustment of product size without human intervention. This high degree of automation ensures that the molding process is not only faster but also more consistent.

Improve production stability and yield

Variations in the injection molding process can lead to defects, increased scrap rates, and ultimately reduce overall production output. The high rigidity structure of the injection unit of the TE II injection molding machine in Topstar’s plastic injection molding machine series. This sturdy design allows operators to control the molding process with extremely high precision and maintain consistent pressure and temperature in each cycle. The TM ll series can also precisely adjust key parameters such as injection speed, pressure, and melt flow. The system increases the melt speed by 10% and boosts the injection pressure by 10%. In addition, they can handle a broader range of product specifications while maintaining excellent quality. The system increases the improved ejection force by 20%, further ensuring that parts demold easily without damage, which helps enhance overall output and create a more efficient production process.

Comprehensive technical support and training

One of the concerns expressed by many manufacturers, especially in emerging markets such as India, is the lack of technical support from international brands. Topstar recognizes the importance of local technical support and commits to providing comprehensive services to customers. In 2025, our customer service center will provide one-to-one on-site training services for customers with specific needs to ensure that every operator is familiar with the operation of our plastic injection molding machines. Our approach includes deep integration into the customer’s production scenarios, accurately locating and solving specific problems encountered in daily operations. This on-site support not only improves operational efficiency but also enhances the overall user experience. At the same time, the company will send technical experts overseas and provide targeted training to local partners to ensure that Indian manufacturers receive timely, efficient, and high-quality technical support.

Providing more valuable injection molding solutions

From solving unstable voltage and high energy consumption to increasing automation and reducing cycle time, our TE II and TM II series machines are carefully designed to meet the diverse needs of the Indian manufacturing industry. In addition, we are committed to providing localized technical support and one-to-one training services to ensure that more customers overseas get the help they need to maximize the performance of our machines.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/02/17

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2025/02/17

- Star Case | Topstar helps Santong upgrade its intelligent plant 2025/02/17

- Topstar Special | National Science and Technology Workers Day 2025/02/17

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC