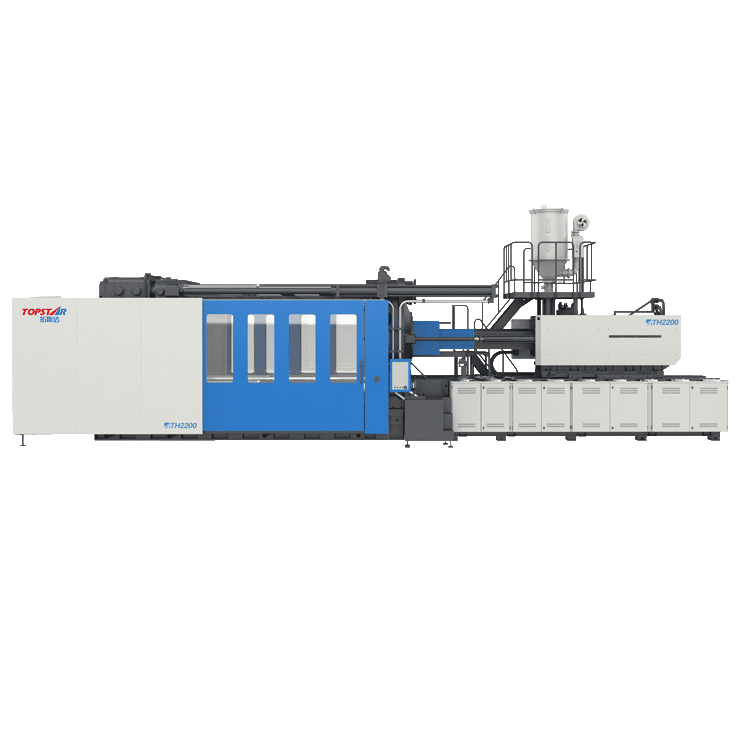

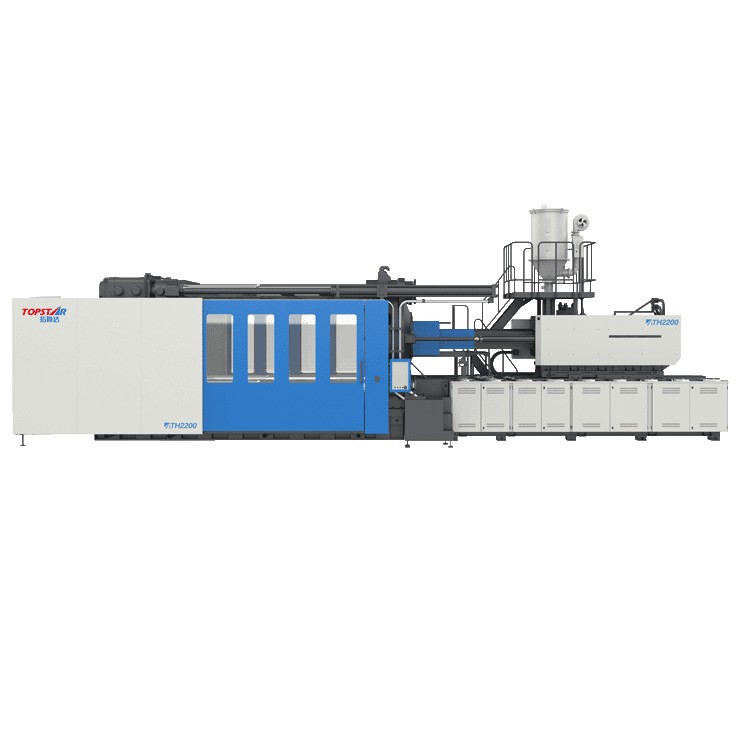

Direct Press Type Injection Molding Machine

Topstar TH Series:Direct Press Type Injection Molding Machine(130T-2800T). TH Series Direct Press Type Injection Molding Machines are divided into two series: small and medium and large. Both series feature standardized clamping and injection platforms. The design adopts a two-plate direct pressure center clamping structure to provide the maximum mold opening stroke. This configuration meets the production requirements for large-format, deep-cavity products and is suitable for automatic part-picking applications.

Characteristics

- Small Direct Press Injection Molding Machine(130T-320T)

- 1. Central direct press clamping structure: Small platen deformation, parallel pressure on the mold, high molding accuracy.

- 2. Double-cylinder for injection, linear guide for moving: Stable injection, sensitive action, high precision.

- 3. Patented sealing ring structure: High sealing reliability and long service life.

- 4. Full series of servo drives: CNC back pressure, KEBA controller.

- Medium and Large Direct Press Injection Molding Machine(550T-2800T)

- 1. Multi-cylinder direct press clamping structure: small platen deformation, parallel pressure on the mold, high molding accuracy.

- 2. Double-cylinder/Four cylinders for injection, a linear guide for moving: stable injection, sensitive action, high precision.

- 3. Patented sealing ring structure: high sealing reliability and long service life.

- 4. Large template spacing, high rigid template: suitable for deep cavity injection molding, product thickness is uniform.

Product Accessories

- 1. Diagonal double injection mold shift oil cylinder and linear guide, more accurate and stable injection.

- 2. An optimized and upgraded platen, with a reliable structure and small deformation, can effectively protect the equipment and improve the mold’s service life.

- 3. High-performance chrome plated screw, durable and efficient, a wide range of applications.

- 4. High color mixing/high mixing screw: to meet the high color mixing products, easy to change color custom screw: specially customized plasticizing components for different products, such as PC, PA, etc.

- 5.Professional matching of plasticizing components to meet the plasticizingrequirements and color mixing performance of different materials.

Adequate supply of goods, available for delivery within 35 days.

Description

Small direct pressure injection molding machine (130T-320T)

Enhanced Clamping Force and Stability

The small direct pressure injection molding machine adopts a central direct pressure clamping structure, which significantly improves the mold closing force and provides rock-solid stability for each injection molding machine cycle.

Precise Dual Cylinder Injection Control

The independent dual cylinder system in the injection molding machine can accurately adjust the injection speed and pressure to ensure uniform melt flow and stable part quality.

Reduce Vibration and Noise

The optimized locking and guiding mechanism work together to suppress the vibration and noise of the injection molding machine, creating a quieter and more reliable production environment.

Medium and large direct pressure injection molding machine (550T-2800T)

Excellent clamping performance

The multi-cylinder direct pressure locking design on the large injection molding machine provides ultra-high mold closing force, which can stably handle large and complex molds.

Flexible injection options

On large injection molding machines, you can choose a dual-cylinder or quad-cylinder injection system to set the speed and precision according to your specific production needs.

Enables versatile large-part production

Designed for demanding applications such as automotive panels, home appliance housings and thick-walled PMMA headlights.