How can EU series injection molding robots shorten cycle time?

2024/08/16 By Topstar

Reducing cycle time is key to achieving higher production and reducing operating costs for manufacturers. When faced with large-volume production tasks, some traditional injection molding robots cannot achieve fast grasping work, and there will be situations such as empty grasping and stopping, which cannot achieve a shortened cycle time. Topstar has developed the EU series injection molding robots to shorten the injection molding cycle time.

High speed of EU series injection molding robot

The EU series injection molding robot uses a lightweight aluminum alloy arm while reducing 20 structural components and weight by 20%. Both are critical to shortening cycle time. In addition, one servo drive on the EU series can directly control 5 servo motors, making the removal control more precise. This drive method allows precise control of all aspects of the grasping process, ensuring rapid and efficient completion of each cycle stage without compromising the final product’s quality. Unlike traditional injection molding robots, the drive only uses 3 CPU chips, realizing a five-axis-in-one design. Each CPU chip controls two axes, and the maximum power of each axis is 750W. This provides powerful power for the robot. This means that each molding process step can be performed with minimal delay, thus reducing overall cycle time.

High precision of EU series injection molding robots

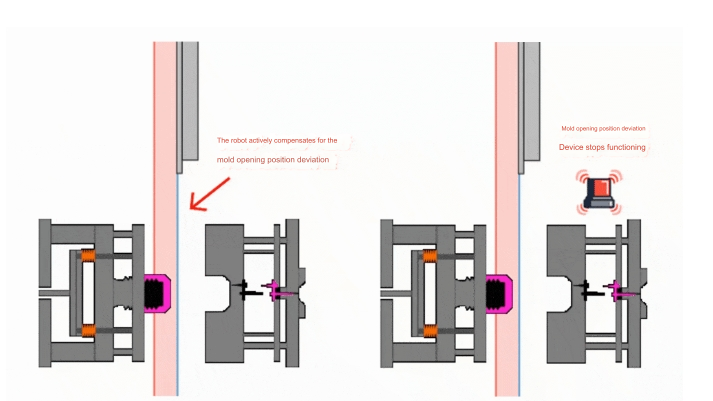

Factors affecting cycle time also lie in the gripping accuracy of the injection molding robot. Traditional injection molding equipment management is to achieve cross-system interconnection through network protocols, which have factors such as signal delay, poor compatibility, and low stability. Topstar is an open architecture through the underlying control system, which enables injection molding peripheral auxiliary machines and injection molding machines to have a native language of system integration, making equipment interconnection an extension of the system rather than just a communication connection. In this way, the EU series injection molding robot can support the host in calling signals and achieving integrated operation. The control system automatically optimizes removal to improve the production line’s injection molding efficiency. We have solved problems such as ejection failure and equipment alarm shutdown caused by ejection position deviation and uncoordinated suction time, improving grasping accuracy and shortening the cycle time.

Energy efficiency and cycle time

Energy efficiency is another key factor affecting the injection molding cycle. While realizing the five-axis-in-one design, the multi-axis common bus design scheme has improved energy efficiency by 20% and reduced electricity costs by 10%. In addition, the servo automatic OFF function has been added to stop the motor from being energized when it is on standby, saving 10% of electricity. This allows them to use energy more efficiently, reducing overall consumption and operating costs. In addition, the servo motor’s precision ensures that each cycle stage is completed quickly and accurately, reducing cycle time. Reduced energy consumption also means that the robot generates less heat, reducing the cooling time required for each part and reducing cycle time.

Efficient material handling

In addition to the characteristics of the EU series injection molding robot, material handling is another important factor affecting the injection molding cycle time. The efficiency of material preparation, transportation and feeding into the molding machine will directly affect the entire cycle time. In the solution of the entire injection molding equipment, we will be equipped with a precise material feeding system to ensure that the right amount of material is delivered to the injection unit at the right time, thereby reducing delays caused by material shortages or overfeeding, both of which will extend the cycle time.

In addition to material feeding, the EU series injection molding robot features an automated material transportation system that simplifies the movement of materials in the production environment, reducing the need for manual intervention. By automating material handling, manufacturers can ensure prompt delivery of materials to the injection molding machine, achieving a more efficient production cycle.

Flexibility and intelligence

When you choose the five-in-one servo EU series injection molding robot, it can be compatible with intelligent upgrades. At the same time, it makes production operations simpler and easy to operate, repair and debug. Networking with the injection molding equipment signal realizes independent injection molding unit automation, and combining series units creates an automated production line. To upgrade the workshop information further, you can access the Tuoxingmai MES system and IOT digital platform through the reserved expansion interface. The diversified terminal enables real-time monitoring and timely optimization of the automated removal process, realizing information management. It allows manufacturers to easily adjust parameters such as injection speed, pressure and temperature to meet the specific requirements of each product. The ability to quickly switch between different production settings reduces setup time and ensures production can proceed smoothly, thereby shortening cycle time.

Comprehensively improve the cycle time of injection molding

The EU series injection molding robot can optimize all aspects of gripping in injection molding. The high precision, speed, flexibility and intelligent all-round performance further improve its efficiency in shortening cycle time, allowing manufacturers to adapt to different production requirements and materials quickly.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/08/16

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/08/16

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/08/16

- Topstar Special | National Science and Technology Workers Day 2024/08/16

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC