What is the average production capacity of a plastic bucket making machine?

2024/07/05 By Topstar

The capacity of plastic bucket-making machine determines their efficiency, profitability, and competitiveness when it comes to making plastic buckets. For manufacturers, the average capacity of plastic bucket-making machines is of concern when purchasing, and it involves the operation arrangement of their entire production workshop. In this blog guide, we will explore with you the range of its capacity and the factors that affect it.

Factors affecting the capacity of the plastic bucket making machine

The capacity of the plastic bucket making machine is affected by many factors, including machine specifications, mold design, material properties, the clamping force, injection rate, and cycle time of different specifications of the equipment. In simple terms, machines with higher clamping forces can accommodate larger molds. The higher the clamping pressure, the more firmly the two parts are fixed, and higher clamping forces also help to shorten the cycle time, thereby increasing potential production. The injection rate determines how fast the molten plastic is injected into the mold, affecting the production cycle’s speed. In addition, the design and quality of the mold used will also affect the cycle time and product quality, and the efficient operation of the operator also plays a role in optimizing and improving production capacity.

Machine specifications and their impact on production capacity

There are several aspects to the specifications. The clamping force of a plastic bucket making machine is usually between 200 and 2000 tons. Higher clamping force generates greater pressure between the molds and allows the handling of larger molds. Different injection rates also vary greatly. Higher injection rates can fill the mold faster, shorten cycle time, and increase production. The design and diameter of the screw affect the injection speed. Screws with high-speed injection designs can process more material in a shorter time, thereby increasing production. Higher injection speeds shorten the duration of the injection phase, thereby shortening cycle time and increasing productivity.

The cycle time of the entire injection molding process, including mold closing, injection, cooling, and mold opening, is also a key determinant of production capacity. To improve the cycle time, in addition to efficient cooling systems and mold opening designs, injection molding robots, and other auxiliary equipment are also needed throughout the production process to simplify operation time and increase production capacity.

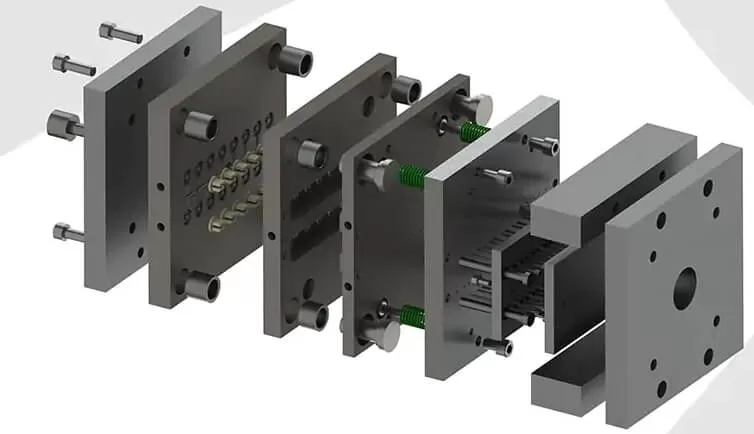

The role of mold design in production capacity

Mold design is another critical factor affecting the production capacity of plastic bucket making machines, which can be divided into single-cavity molds and multi-cavity molds. Single-cavity molds produce one bucket per cycle, while multi-cavity molds can produce multiple buckets simultaneously. Multi-cavity molds increase production capacity by increasing the number of units produced per cycle. However, they also require more complex design and precision to ensure consistent cavities. The design and placement of cooling channels within the mold are essential. An efficient cooling channel cools the plastic evenly, reducing cooling time, which is also essential to the overall cycle time. Faster cooling speeds result in shorter cycle times, directly increasing production capacity.

Material properties and their impact on output

The type of plastic material used in the injection molding process also affects the capacity of the plastic bucket making machine. Common materials include HDPE, PP, and PVC. Each material has different flow characteristics, cooling time, and shrinkage, which affect cycle time and total output.

Lower-viscosity materials make it easier to flow into the mold cavity, thereby reducing the required injection pressure and filling time. This can shorten cycle time and increase productivity. High-viscosity materials require more extended pressure and filling time.

The melting temperature of the plastic resin affects the heating of the molding cycle. Materials with lower melting points require less energy and shorter heating time, which helps to shorten the molding cycle and increase production capacity. Materials with high thermal conductivity calm and solidify faster, reducing cooling and overall cycle time. Therefore, selecting resins that meet the requirements and are compatible with the plastic bucket is necessary while optimizing processing parameters such as injection pressure, temperature, and cooling time based on material properties to ensure efficient production.

Production capacity of plastic bucket making machine

Knowing so many factors that affect the production capacity of plastic bucket making machines, what is its production capacity? There are machines of different specifications and models in Topstar, each with a different production capacity. On average, these machines can produce 50 to 100 barrels per hour, depending on the specific model and configuration and the size of the plastic barrel. Small machines are usually used for limited or specialized products and may produce about 100 per hour. In contrast, some large plastic barrels may produce about 50 per hour.

Choose the right equipment

Plastic barrel manufacturers can make relevant decisions on equipment investment and production strategy by considering machine specifications, mold design, material properties, etc. As technology continues to advance, the functions of plastic barrel making machines will continue to be updated and iterated while also providing manufacturers with opportunities for high output and efficiency.

TRENDING POSTS

- TOPSTAR Global Open Day 2025: Humanoid Robot Debuts, Pioneering a New Decade of Intelligent Manufacturing 2024/07/05

- Topstar Showcases TE II Electric Injection Molding Machines at InterPlas Thailand 2025 2024/07/05

- Topstar Expands Its Ecosystem Partnerships to Drive Smart Manufacturing Innovation 2024/07/05

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/07/05

HOT TOPIC

- .ervo motor-driven linear robots

- •

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 160℃ mold temperature controller

- 170 ton injection molding machine

- 2

- 21

- 220-ton injection molding machine

- 23

- 260 ton injection molding machine

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 460T injection molding machine

- 5-axis CNC machine

- 62

- 90 ton injection molding machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- all-electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- auto loader

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- automotive parts injection molding

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- Digital Transformation

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-efficient water chiller

- energy-efficient water chillers

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Flexible Production Line

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- granulator machine

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- high-speed electric injection molding machine

- High-Speed Packaging Injection Molding

- Honeycomb rotor dehumidifier

- Hopper Dryers

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial AI

- Industrial Automation

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- injection molding process

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Intelligent Factory

- intelligent injection molding machines

- Intelligent Manufacturing

- intelligent mold temperature

- intelligent mold temperature controller

- Intelligent mould temperature controller

- InterPlas Thailand 2025

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- Large flow water type mold temperature controller

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- Manufacturing Innovation

- medical grade injection molding machines

- Medical Injection Molding

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- mobile cover making machine

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding machine

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- optical component injection molding

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- packaging injection molding

- Packaging Solutions

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- phone cover making machine

- PID Control Mold Temperature Controller

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- plastic molding

- Plastic Molding Industry

- Plastic Molding machine

- plastic molding machine 1

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection molding machine

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-driven injection molding machine

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Smart Manufacturing

- soundproof granulator

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robot

- take-out robots

- Thailand 4.0

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- TIC2000 Control System

- TMII injection molding machine

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Electric Injection Molding Machine InterPlas Thailand 2025 Smart Manufacturing Thailand 4.0

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar