Home / How much does an injection molding machine cost?

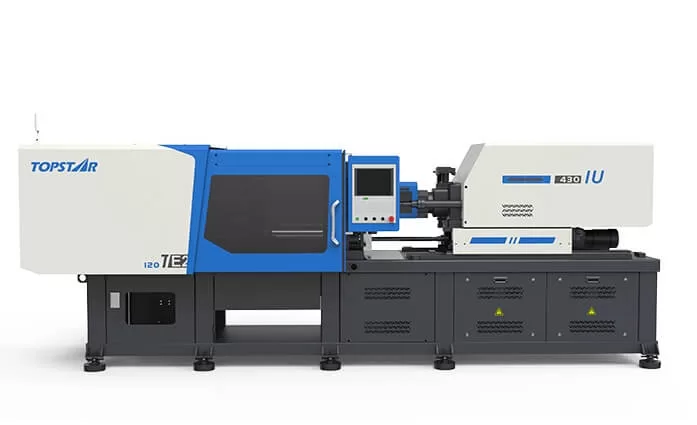

When purchasing an injection molding machine, price is often the first thing most buyers pay attention to. Topstar will invest heavily in type, size, features, and operating costs as an injection molding machine manufacturer. Cost is also one factor determining the market Injection molding machine price. We will discuss this in this guide and let you know how much it costs.

The type and size of the injection molding machine determine price!

Injection molding machine prices can vary significantly depending on the type and size of injection molding machine selected. Generally speaking, there are three main types of machines: hydraulic, electric, and hybrid. Hydraulic presses are generally cheaper but consume more energy and are relatively slower than motors, which are more precise, faster, and energy-saving but have a higher initial cost due to imported servo motors inside. Hybrid machines combine the best features of hydraulic and electric systems to provide good energy efficiency and high-speed operation without the high cost of all-electric models. Their prices are also in the mid-to-high range.

The size of the injection molding machine is usually expressed in terms of clamping force and injection volume. The size will also affect the cost and price. Small and medium-sized machines have lower tonnage and lower machine prices and are more suitable for producing small items with exquisite details. The tonnage and size of large machines will make the price and cost higher and require a large amount of energy and material consumption, which is suitable for producing large items.

The characteristics of the injection molding machine determine the cost and price

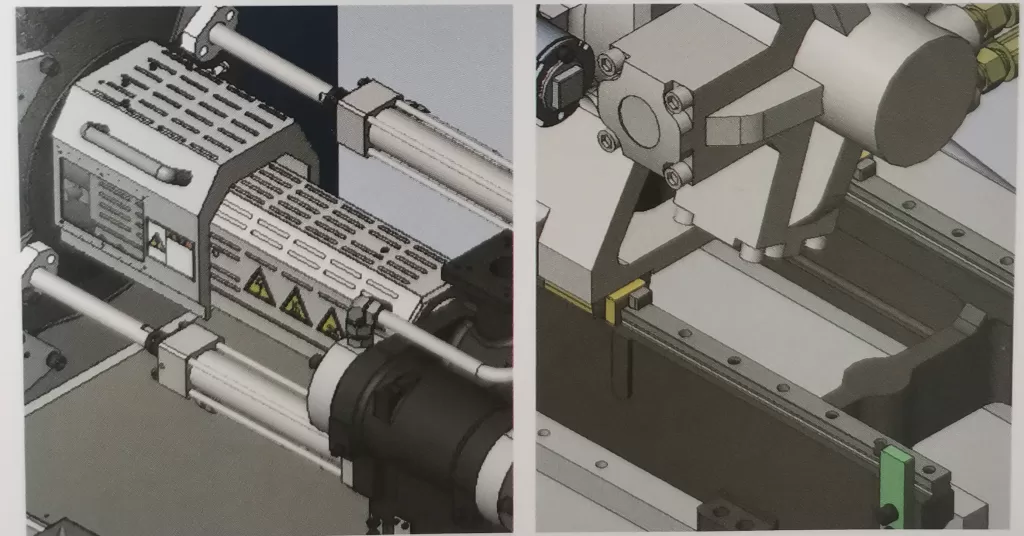

Another factor that significantly affects cost and price is its properties. In addition to the standard features on the basic models, design features such as one-touch mold adjustment function, super design of template size, advanced injection molding, clamping, hydraulic system design, etc., on different series of machines will affect the injection molding machine price. Many machines will adopt technologies to reduce power consumption and improve efficiency to improve energy efficiency. In developing and researching these technologies, manufacturers will invest more in costs and the workforce to execute them. These may increase the initial cost, but in the long run, they are savings.

Associated operating costs

While many buyers will focus on the upfront injection molding machine price, the operating costs associated with the equipment should also be considered. Energy costs are one of the most significant ongoing expenses in operating an injection molding machine. A lot has to do with the type and efficiency of the injection molding machine, as well as the complexity and duration of the molding cycle. Electric motors are generally more energy efficient than hydraulic machines because they consume electricity when necessary and have precise energy control. Hybrids offer a balance, using electricity for precision and hydraulics for power.

Regular maintenance is also important for injection molding machines to ensure continued efficient operation and prevent sudden shutdowns. This includes routine inspections, replacement of worn parts such as seals and hoses, and more critical repairs involving hydraulic systems or electrical components.

Market trends that affect prices

Market trends and economic factors in different countries will also affect the cost of injection molding machines. Technological advancements, fluctuations in raw material costs, and changes in the labor market will all affect machine prices.

Technological innovation and improvement are some of the main factors responsible for the price changes of injection molding machines. As manufacturers introduce new features to improve efficiency, speed, and product quality, the costs and prices gradually increase. The increase in the cost of raw materials used to manufacture the equipment also directly affects the price. Global economic conditions, export trade policies, and other factors may affect the cost fluctuations of these materials.

The global economic landscape will also affect the price of the entire injection molding machine market. In some countries and regions experiencing economic recession, reduced manufacturing activities and capital expenditure budgets will result in fluctuations in demand and price declines.

Choose the right supplier

The quality of the supplier also affects the cost. Suppliers with a good reputation for quality and service usually offer machines at a higher price. This is because they use better materials and precise manufacturing processes. Another key aspect that affects long-term costs is the supplier’s after-sales support. Suppliers that provide comprehensive services, technical support, and readily available spare parts can also help minimize downtime and maintenance expenses. A manufacturer that can offer a high price must have its own excellent technology and selling points.

Make informed decisions

In short, injection molding machine price is related to the machine’s type, size, features, and operating costs. As you will learn from this guide, the cheapest option is not always the most cost-effective in the long run. Instead, you need to consider all aspects of your investment. You need a machine that can support the long-term growth of your business.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/05/10

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/05/10

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/05/10

- Topstar Special | National Science and Technology Workers Day 2024/05/10

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

Afrikaans

Afrikaans Albanian

Albanian Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) English

English French

French Portuguese

Portuguese Russian

Russian Spanish

Spanish Turkish

Turkish