Are electric injection molding machines a better choice?

2024/04/22 By Topstar

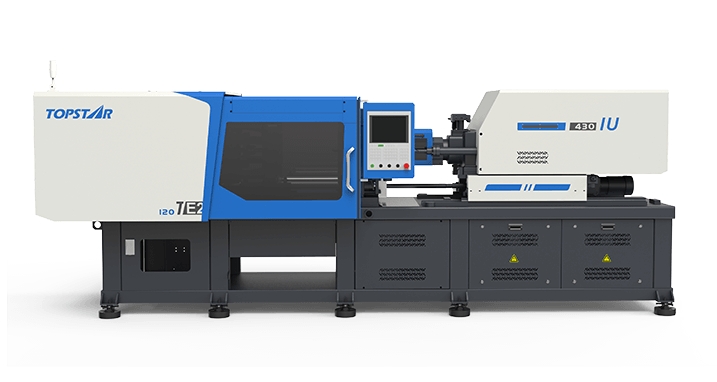

Are electric injection molding machines better than hydraulic injection molding machines? This is a question that many users will ask when purchasing an injection molding machines. Hydraulic injection molding machines are a more traditional type. They use hydraulic drive technology to perform injection molding. However, in recent years, everyone has tended to use electric injection molding machines to perform work, finding that they are more efficient and cleaner. We will tell you whether electric is better than hydraulic by comparing the advantages and disadvantages of the two.

Energy efficiency of injection molding machines

The advantage of electric is energy efficiency. Active actions such as mold closing, mold opening, glue injection, and glue melting are all fully electric controlled, which consumes power only when needed, significantly reducing energy consumption. In contrast, hydraulics require a hydraulic pump to run continuously when working, and based on our user feedback and its practical applications, using electric motors can save up to 50% – 70% of energy compared to hydraulics. This energy efficiency directly reduces operating costs while increasing productivity.

Accuracy and speed of electric injection molding machines

The precision of electric injection molding machines is mainly reflected in their use of direct drive from servo motors. This precise control enables consistent process parameters and significantly reduces injection cycle variability. In addition, their repeatability ensures that they can be replicated with extremely high accuracy every cycle, ensuring that each part produced is nearly identical to the last. This repeatability is critical for medical devices. The difference is that the entire injection molding cycle of hydraulic injection molding machines is not as fast as that of electric ones, and the cleanliness rate of the parts they mold does not meet the standards of some specific industries.

Maintenance requirements

Electric ones have relatively low maintenance requirements. They utilize servo motors and ball screws to operate and do not require hydraulic oil. This factor alone can lead to related maintenance tasks such as checking oil levels and changing filters and leaks. And not using hydraulic oil in the motor also reduces the risk of contamination of molded parts. The overall wear rate of their motor components is also lower than that of hydraulic components, and maintenance is not expensive.

For hydraulics, the maintenance requirements will be higher. They rely on hydraulic fluid to operate and require regular monitoring and replacement to ensure optimal performance and avoid breakdowns. Maintenance of the entire hydraulic system also includes regular replacement of hoses, seals, and pumps. In comparison, they require a more tedious maintenance process.

Purchasing and operating costs

Electric machines generally cost more than hydraulic machines due to their motor drive system. These components provide greater control and efficiency but cost more. In comparison, the price of hydraulics will be lower, suitable for most manufacturers, and the environmental requirements will not be high. Electric is more cost-effective for the operating costs of the two, and this capability significantly reduces energy consumption compared to hydraulic machines, even during idle periods.

Noise level during operation

Compared to hydraulics, electrics are quieter during operation. Since there is no hydraulic pump and a constant flow of hydraulic oil, the main source of noise in the hydraulic system is eliminated. For hydraulic injection molding machines, the noise during operation is often high. The noise source is the pumps and motors required to maintain the flow of high-pressure hydraulic oil during operation. The action of hydraulic oil under pressure through valves and actuators generates large amounts of sound energy, creating noise.

Ultimately

Although electric injection molding machines are better than hydraulic ones in terms of injection efficiency, precision, speed, and operating costs, their upfront purchase costs are relatively high. They are not the best choice for small and medium-sized manufacturers. In most cases, electric power will be better than hydraulic power, but the final choice depends on your own industry and conditions.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/04/22

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/04/22

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/04/22

- Topstar Special | National Science and Technology Workers Day 2024/04/22

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC