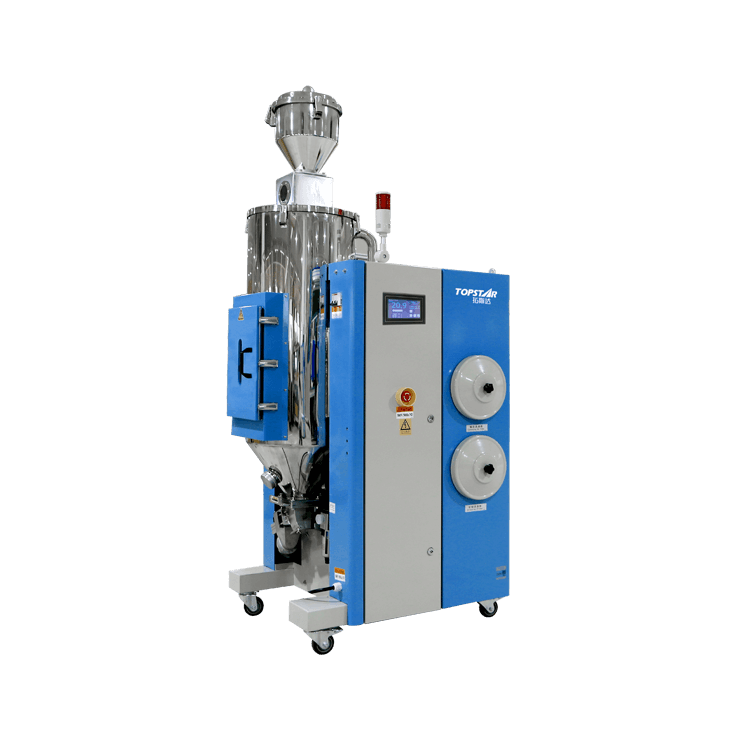

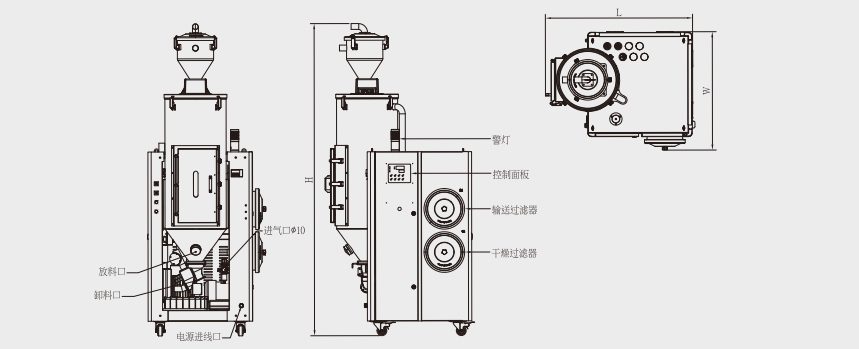

Topstar standard type: 3 in 1 Compact Dehumidifying Dryer

2024/02/12 By Topstar

Many customers use three devices for dehumidification and drying, which is very wasteful and takes up space. Therefore, we have launched a 3 in 1 Compact Dehumidifying Dryer. It combines three functions of dehumidification, drying, and feeding into one machine. The 3 in 1 design takes up no space and is small. It is especially suitable for places with high automation and multiple protection devices. It is ideal for areas with tight spaces.

The 3 in 1 Compact Dehumidifying Dryer uses a Ceramics Honeycomb Rotor Dehumidifier

One of its core components is the ceramic honeycomb rotor dehumidifier. It comprises a rotating honeycomb structure made of ceramic materials with excellent hygroscopic properties, which can obtain low dew point (-40°) dry air with good stability. As ambient air passes through the honeycomb, moisture is adsorbed, effectively reducing humidity and ensuring the plastic pellets remain dry before entering the molding process. Additionally, the honeycomb structure maximizes the surface area available for moisture absorption, thereby increasing the system’s overall dehumidification efficiency.

Stainless insulated hopper dryer

We used stainless steel because durability, cleanliness, and energy efficiency were our primary considerations. The drying device of the 3 in 1 Compact Dehumidifying Dryer device adopts a Stainless insulated hopper dryer, which optimizes the drying of plastic particles and ensures corrosion resistance by guiding hot air upward through the plastic particles. This method ensures even heat distribution and prevents temperature changes from affecting drying efficiency. Introducing hot air from the bottom reduces heat loss, thereby improving energy efficiency, reducing costs, and enhancing the consistency of product quality.

Stainless autoloader for 2 -stage or 3- stage

Its feeding part uses a stainless autoloader for 2 -or 3-stage, emphasizing durability, cleanliness, and feeding accuracy. The multi-stage feeding mechanism allows precise material flow control, optimizing the injection molding process for various applications. Equipped with a shut-off valve, this device prevents residual material from accumulating in the pipeline between different production runs, eliminating the risk of cross-contamination and ensuring the purity of the injected material, ensuring no residual raw material remains in the feed pipe.

The 3 in 1 Compact Dehumidifying Dryer adopts PID temperature control system

Because traditional drying and dehumidification systems are inaccurate in temperature adjustment, causing temperature differences to affect product quality, we use a PID temperature control system on the 3 in 1 Compact Dehumidifying Dryer to improve the accuracy and responsiveness of temperature adjustment, as well as maintain Dew point stability. By ensuring dew point stability, injection molding equipment prevents moisture from forming within the plastic pellets, minimizing the risk of defects and ensuring the production of a high-quality end product.

3 in 1 Compact Dehumidifying Dryer adopts multiple fault intelligent alarms

In traditional dehumidification and drying systems, the alarm system is relatively simple and can only detect one or two problems. This leads to many issues that require us to find manually, which consumes time and workforce. The 3 in 1 compact dehumidifying dryer integrates various intelligent fault alarm systems, including three-phase power reverse phase shortage alarms and phase loss alarms, heater failure alarms, fan overload alarms., etc.

It monitors the power supply and alerts the operator during phase reverse or loss, ensuring proper power distribution. If the system detects a heater failure, it triggers an alarm to prevent potential issues such as drying or insufficient dehumidification. It can also monitor fan performance and trigger alarms in the event of overload. Prevents fan overload to maintain consistent airflow and efficient materials.

Improve injection molding drying level

With the advent of the intelligent era, we are no longer limited by the low-efficiency injection molding drying mode in the past, so the emergence of the 3 in 1 Compact Dehumidifying Dryer is precisely to enable more injection molding manufacturing to move towards intelligent and efficient work. This way, we can improve operational efficiency and create more reliable products.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/02/12

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/02/12

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/02/12

- Topstar Special | National Science and Technology Workers Day 2024/02/12

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC