What are the main functions of the Swing Arm Robot in injection molding?

2023/12/20 By Topstar

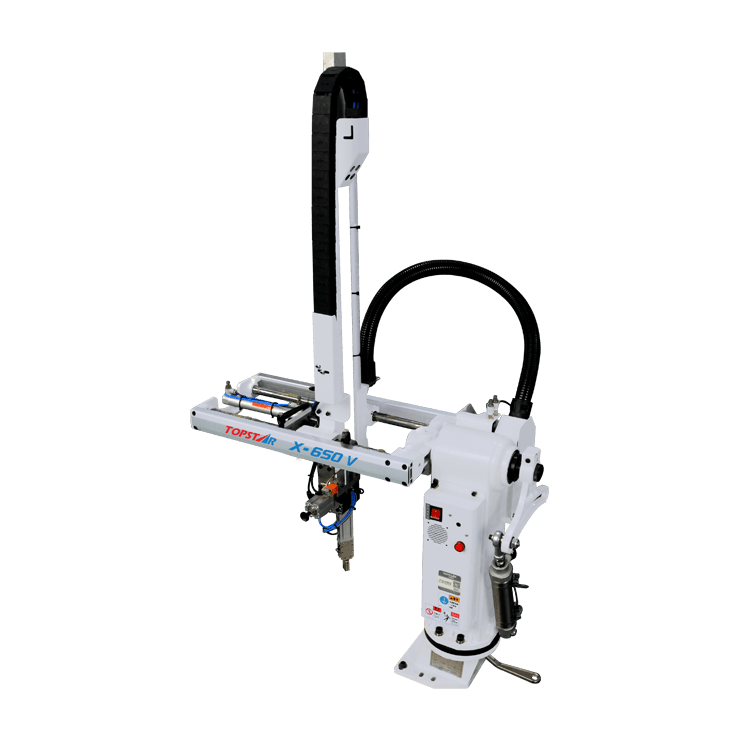

Today, we introduce Topstar’s swing arm robot to you. Swing arm robots are indispensable tools in injection molding and other manufacturing industries. Like other injection molding robots, they can also improve efficiency, precision, and overall automation to a higher level. Of course, they also have their advantages. Let’s take a look!

High-speed material handling with swing arm robot

The swing arm robot is characterized by a multi-joint structure similar to the flexibility of human limbs. The arms are available in single-stage and telescopic types. The single-stage vertical travel is 650mm, and the telescopic vertical travel is 750mm. This design enables them to navigate complex spaces and perform fast, coordinated movements. Additionally, these robotic systems excel at transporting materials between various workstations, sorting and stacking molded parts, and loading/unloading items on conveyor belts. The high-speed capability of the swing-arm robot ensures continuous, seamless material flow, maximizing injection molding machine utilization.

Automate repetitive tasks with the swing arm robot!

Swing-arm robots in injection molding can operate well on the production line and quickly transfer molded parts on the injection molding machine between workstations. Their flexibility allows them to adapt to various mold configurations, optimizing production for different product lines. By integrating additional software, these robots can be programmed to perform complex movements, handle delicate materials, and perform complex tasks, thereby reducing the need for human intervention. Swing-arm robot automation also reduces hazardous environments, reduces waste, and increases overall productivity. They create a more dynamic and efficient injection molding environment, reducing operator work and stress.

Achieve consistent part placement with swing arm robots!

These swing arm robots use advanced gripper sensors to rotate products 90°. Through real-time feedback from sensors, the robotic arm can adjust its movement to adapt to changes in the molding process, thereby ensuring a high degree of consistency in part and particle placement. When we perform work tasks, we equip the robotic arms with corresponding programming for different injection molding machines to ensure that they accurately place each part in the injection molding environment and reduce waste and losses.

More flexibility when changing molds

Key to their flexibility is programmability and adaptability. Operators program robotic arms, not manual labor, for precise mold changes, ensuring efficiency in contrast to traditional methods. The end effector of a robotic arm or the tool attached to its end can play a critical role. Specialized end effectors enable the robot to grasp, lift, and change molds of different shapes and sizes. Advanced sensors and vision systems will allow the arm to accurately identify and position molds, ensuring smooth transitions between production runs. Their ability to work in limited spaces and tight tolerances makes them ideal for complex die-change jobs.

Adaptable programming for various injection molding needs

Swing arm robots can be programmed and customized for specific applications, molding requirements, and materials. This versatility allows a variety of plastics manufacturers to optimize robot performance for different production scenarios and injection molding machines, making them an indispensable tool for facilities with different injection molding needs. As the injection molding process diversifies and becomes more specialized, the adaptability of swing-arm robots makes it a key asset for manufacturers seeking a competitive advantage in a rapidly changing industry. Having this capability gives swing-arm robots a more significant competitive advantage.

In the end

The above description of several aspects of the swing arm robot can let operators and manufacturers know the role this type can play in the injection molding industry and other industries. Swing-arm robots are indispensable industrial robots in every manufacturing industry. We must understand their information and situations more clearly to help us complete our tasks.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/12/20

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/12/20

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/12/20

- Topstar Special | National Science and Technology Workers Day 2023/12/20

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC