Key design parameters of Toggle Clamp Injection Molding Machine

2023/12/11 By Topstar

The Toggle Clamp Injection Molding Machine has high efficiency and excellent results and is widely used to produce various non-plastic products. This study will focus on the critical design parameters of Toggle Clamp Injection Molding Machines to popularize relevant knowledge. Understanding these parameters can help us perform better when designing and developing these machines. As operators, It is also possible to operate and use them better.

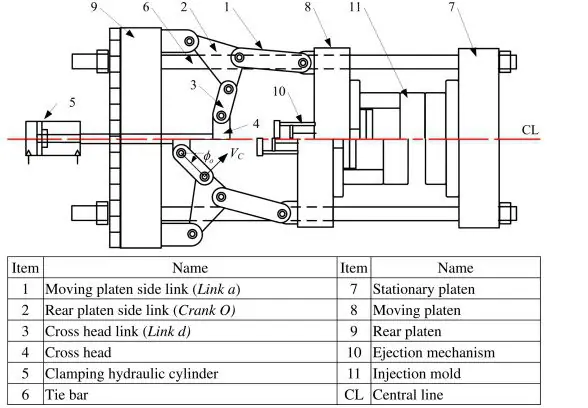

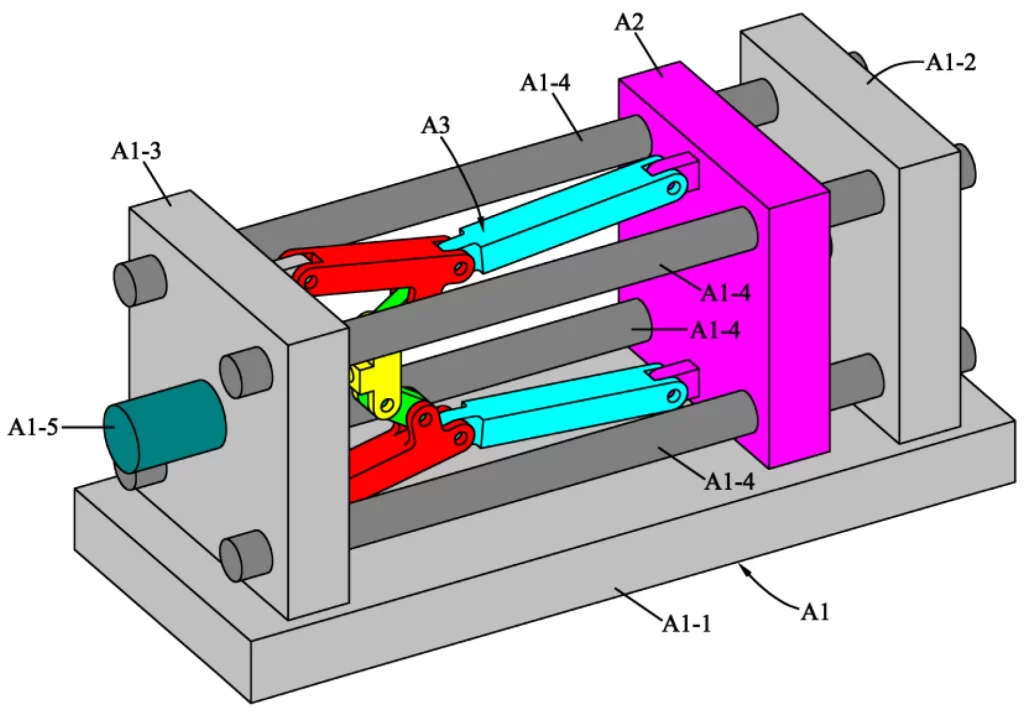

Toggle clamp mechanism of Toggle Clamp Injection Molding Machine

The toggle clamp mechanism of the injection molding machine is a complex engineering design. The tool consists of a series of hinged joints and levers. It is carefully designed to have excellent strength and flexibility and can accurately control the clamping force. Provides necessary clamping force during the molding cycle. The toggle clamp structure operates by taking advantage of the mechanical benefits gained from its linkage arrangement. When a clamping pressure is applied to secure the mold, the hinged joint can dynamically and effectively transmit the power, ensuring the safe closure of the mold during the injection process. The toggle mechanism has the advantages of efficient movement and energy saving, so it is commonly used in the mold closing mechanism of injection molding machines.

Design of injection device of Toggle Clamp Injection Molding Machine

The core of the injection unit is the screw design, which is a fundamental aspect that affects the uniformity of the molten material. The length, diameter, and pitch of the screw are carefully designed to optimize material melting, mixing, and injection. Their design parameters can also directly affect injection speed and pressure, critical factors in maintaining dimensionally accurate molded parts.

The barrel heating system is also an essential part of the injection device. Precise temperature control along the barrel ensures the molten material maintains its viscosity, allowing for even flow and distribution. Material delivery mechanisms, including the use of reciprocating screws or barrier screws, further refine the design of the injection unit. These mechanisms influence the dosing and injection phases, allowing fine-tuned injection process control. The choice of material delivery mechanism is tailored to the specific requirements of each molding application.

Clamping force

The clamping force of the toggle clamp injection molding machine determines the machine’s ability to hold the mold during the injection molding process. Calculating clamping force involves factors such as the size and shape of the mold, the material being injected, and the accuracy required for the final molded product. Please refer to this report for details.

Locking force is a critical design parameter; too much pressure can cause premature wear, affecting machines and molds, while too little energy can affect the quality of the final product. Achieving the right balance is critical for consistent and high-quality molding results. Toggle Clamp Injection Molding Machines usually use advanced technologies such as sensors and real-time feedback systems in the locking force mechanism. These innovations enable precise monitoring and control, ensuring dynamic adjustment of the clamping force to meet the changing needs of different molding applications.

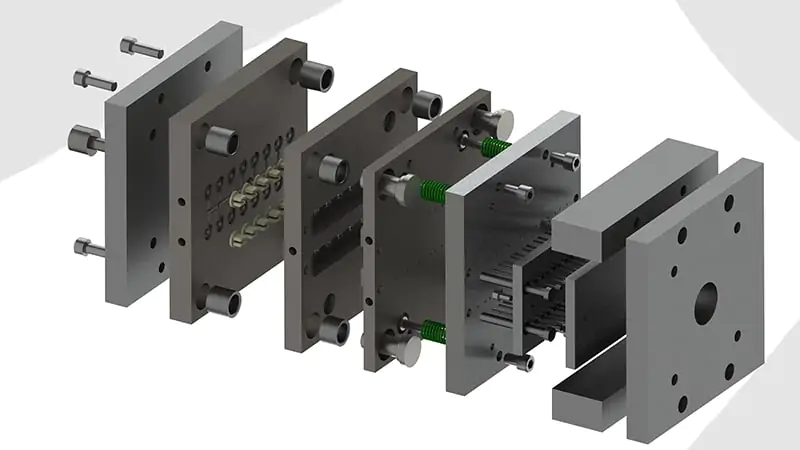

Mold design

Engineers carefully craft molds based on the specific requirements of each product. Critical considerations in mold design include size, shape complexity, and the overall geometry of the target product. Engineers use CAD tools to create 3D models that allow the mold structure to be visualized.

Cooling system integration is another important aspect of mold design. Carefully placed cooling channels help dissipate the heat generated during the injection process, shortening cycle times and increasing overall productivity. They help maintain even temperature distribution throughout the mold, ensuring consistent part quality. The exhaust and ejection mechanisms are an integral part of the mold design. Proper exhaust provides the discharge of air and gas during the injection process and prevents defects such as air pockets.

Hydraulic system efficiency

Toggle Clamp The hydraulic system in an injection molding machine provides power for essential functions such as mold clamping, injection, and ejection. At its core, it carefully sets design parameters such as pump capacity, pressure control mechanisms, and energy recovery systems. The goal of the injection molding machine engineer is to put these parameters in a balanced manner to ensure that the hydraulic system provides sufficient power for the machine to operate seamlessly while minimizing unnecessary energy consumption.

Variable speed drives play an essential role in hydraulic system efficiency. These drives allow pump speed to be dynamically adjusted, matching power output to the machine’s instantaneous needs. A regeneration system also further improves hydraulic efficiency. During the deceleration phase, the energy generated is recovered and directed back into the system, thus reducing overall energy consumption.

Final

This guide considers clamping force, injection setup, hooking mechanism, hydraulic system efficiency, and mold design. These five key design parameters are popularized so that everyone can better understand the toggle clamp injection molding machine so that they can be more easily controlled during design, development, and operation.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/12/11

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/12/11

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/12/11

- Topstar Special | National Science and Technology Workers Day 2023/12/11

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC