2022 best Guide to Choose cnc Machine Shop

2022/03/08 By Topstar

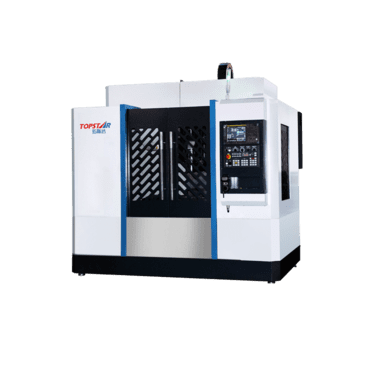

Cnc machine shop has technological machine devices that control machine tools by automatic control system to help optimize work such as reducing cost, time and labor force.

The process of controlling the device to move in any straight or curve direction by industrial computer or specializes control. CNC machines can apply in 2D, 3D, etc. Currently, CNC machines are being widely uses in 3D space and implement by specially design software.

In the current mechanical processing industry, CNC machines are widely and popularly apply such as: CNC cutting, coding, pattern CNC cutting, CNC engraving & laser engraving, wood & stone cutting machines with meticulous shapes, complex to ensure the sophistication and high aesthetics of the product. Meanwhile, traditional metal cutting machines can only handle cuts of certain shapes and shapes.

Working principle of cnc machine shop

CNC machines uses today on the cnc machine shop are very diverse in terms of products, shapes, different functions and working capabilities, which classify according to each CNC machine as follows: CNC lathes are widely uses and most of them process to shape rotating parts to reduce labor costs and improve product accuracy in mass production.

Functions of CNC milling machine

A CNC lathe has a basic structure including: machine body, tool drive, chuck, CNC control panel, main shaft, main drive motor, and dynamic chuck. There are two common types of CNC lathes: 2-axis turning or 4-axis turning. A CNC lathe is a machine that is both turning and milling, and can process many complex shapes.

What are the disadvantages of CNC Milling Machine

A CNC milling machine is a method of cutting metal through a rotating tool calls a milling cutter. The outstanding feature of the milling machine is high productivity and great accuracy, the milling cutter has many cutting edges to help limit blade wear, using a large number of tools.

Using a cnc machine shop significantly reduces the manufacturing time on multiple fronts when it comes to prototyping or mass manufacturing.

The disadvantage of CNC milling machines is that the collision of the cutting edges and the machined surface causes vibrations that affect the accuracy of each part and surface quality, often the gloss is not high.

CNC Grinding Machine

sO, CNC grinding machines uses to sharpen milling cutters and mainly grind on surfaces: surfaces, cylinders or complex shapes. CNC grinding machines have outstanding features such as: a high degree of automation, measuring tools and tools are integrated in a large number of automatic machines, allowing extended production time automatically.

CNC Drilling Machine

So, Cnc machine shop is usually computer control and application deploy for mass production in large quantities. NC drilling machines are suitable for applications with any shape and work piece. Due to the application of detailed and meticulous processing, CNC drilling machines are also diverse in size and model. There are 2 main types of CNC drilling machines such as:

Table Drill: Used to drill holes through rough parts (wood, plastic and metal).

Rod drill: used to drill with larger size and tonnage of material and make large hole drilling. And is considered a larger version of the bench drill and stands upright on the floor.

CNC Engraving Machine

So CNC engraving machines import to China and have different sizes, dimensions and features such as: CNC engraving machines, CNC punching machines, CNC engraving machines,…

CNC Cutting Machine

So, Cnc machine shop use pre-programmed CNC technology combined with a number of methods to apply to cutting materials with programmed shapes on the machine. NC cutting machines mainly uses in the metalworking industry. Bases on the structure of the CNC cutting machine, people divides into the following types: CNC plasma cutting machine for metal processing.

CNC plasma cutting machine apply CNC technology and at the same time the plasma source (arc generator) to increase the temperature to melt metal materials.

What is the application of cnc machine shop?

– CNC machines have processing applications in the mechanical or mechanical engineering industries. The ability to process on multiple materials (wood, stone, metal, ..) helps CNC machines widely available today.

– Household appliances production applications: With precise and meticulous requirements, high gloss is found in most household products. With CNC software programmed, precision in stitching is essential and pre-programmed mold creation, popular items such as electrical appliances, refrigeration, household appliances.

– In the shipbuilding cnc machine shop, when you need to process cipher text or cut thick materials, a plasma cutter is indispensable. In addition, the plasma cutter can process decorative patterns such as railings, gate doors, partitions, .Cnc machine shop manufacturers to work at a much faster pace while delivering the same high standard of products.

What is working principles of cnc machine shop?

Plasma cutting CNC machines work with a plasma jet to cut conductive metal materials. The gas sources uses are: hydrogen-Argon mixture, Oxygen, Nitrogen… because these gases do not conduct electricity when in normal state.

However, when you give them a large flow of energy to ionize the gaseous atoms, they become capable of conducting electricity. The strong gaseous oxidation process will create a plasma stream. The plasma beam reaches the cutting head and is capable of cutting metal.

What is the application of CNC machine?

– CNC cutting machines have processing applications in the mechanical and mechanical engineering industries. With the ability to process on many materials such as wood, stone, metal (cutting iron, stainless steel…).

– Application in the household appliance industry: With precise techniques from cnc machine shop programming software, the surface of household products is cut precisely and meticulously with high gloss and standard. So it is apply in making molds for electrical appliances, refrigeration, household appliances, etc.

Applications in the shipbuilding industry:

With the ability to cut thick materials, plasma cutting machines are very suitable for processing cipher texts for the shipbuilding industry in China. In addition, the plasma cutter can also process decorative patterns such as railings, gate doors, partitions…

Besides, the high-precision laser cutting machine is suitable for processing parts and spare parts that require high precision.

Where to buy good quality CNC machines, where is the cheapest?

Good quality CNC machines are sold in most mechanical cnc machine shop these days. However, not everywhere sells good quality CNC Machines at cheap prices.

If you are not careful when buying, it is easy to buy CNC machines, poor quality components, high prices reduce productivity, work efficiency and add time consuming maintenance, Product replacement is often due to poor quality.

Hope this article will help you better understand what is milling machine?

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/03/08

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/03/08

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/03/08

- Topstar Special | National Science and Technology Workers Day 2022/03/08

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC