From polymer to product: the key role of the plastic injection machine

2023/09/29 By Topstar

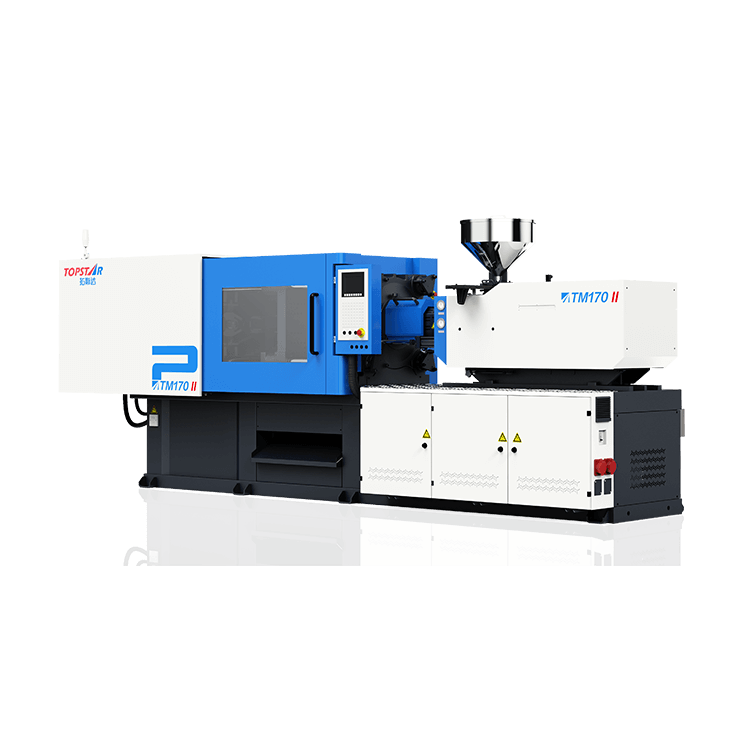

In the complex world of plastic manufacturing, plastic injection machine have been working tirelessly to advance the industry. While it may not receive as much attention as some other technological marvels, its importance cannot be overstated. In this article, we’ll take a closer look at the critical role plastic injection machines play in our daily lives, exploring their journey from polymer to product.

The birth of precision plastic injection machine

At the heart of plastics manufacturing are plastic injection machines, which quietly transform polymer raw materials into a range of products we rely on. These machines are masters of precision, capable of shaping objects with incredible consistency. The process is deceptively simple: Polymer pellets are melted and injected into a mold to form a specific shape. The devil, however, is in the details. Mold design, temperature control and pressure regulation are all carefully tuned to ensure each product meets strict standards.

The level of precision of plastic injection machines is particularly important in industries such as aerospace, where even the smallest defects can have catastrophic consequences. It’s no exaggeration to say that the modern world that relies on precision-engineered products owes a debt to these obscure manufacturing craftsmen.

Innovation takes place in plastic injection machine

One of the most notable qualities of a plastic injection machine is its adaptability. It is a workhorse across industries, producing everything from tiny smartphone parts to rugged auto parts. Their versatility is a testament to human ingenuity and engineering prowess. They don’t discriminate based on product complexity – they just get the job done with precision and efficiency. This adaptability enables manufacturers to streamline production processes and reduce costs, ultimately benefiting consumers by offering a variety of high-quality products at affordable prices.

Sustainability in plastic manufacturing

Plastics face their fair share of environmental criticism, but plastic injection machines play an important role in making manufacturing more sustainable. They manufacture products with precision to optimize material use, minimize waste and reduce energy consumption. Innovations in materials and recycling processes further promote environmentally friendly manufacturing. By using plastic injection machines responsibly, we can solve some of the problems associated with plastic production.

The sustainable advantage of plastic injection machines is their ability to minimize waste. Unlike other manufacturing processes that generate large amounts of waste and require extensive post-processing, injection molding generates very little waste. Any excess material can often be recycled and reused in subsequent runs, reducing the environmental footprint of each product.

Their progress and possibilities

The manufacturing industry is constantly evolving, and plastic injection machines are evolving with it. The convergence of smart technologies is increasing its efficiency and productivity. Real-time monitoring and adjustments become commonplace, driving further improvements. Additionally, research into biodegradable and sustainable materials is reshaping the industry, bringing hope for greener plastic products. Looking to the future, plastic injection machines will continue to play a key role in shaping the world around us.

Advances in automation and digitalization are reshaping the way plastic injection machines operate. Smart sensors and data analytics enable manufacturers to monitor every aspect of the injection process in real time and make adjustments as needed to ensure consistent quality. Predictive maintenance is also becoming a reality, reducing downtime and increasing overall efficiency.

Skilled operator

Behind the meticulous operation of the injection molding machine, there are skilled operators who ensure that everything runs smoothly. These professionals are the unsung heroes of the factory floor, monitoring machines, fine-tuning settings and troubleshooting problems. They have a deep understanding of the intricacies of injection molding and are able to adjust parameters to achieve the desired results. Their expertise is invaluable in maintaining production quality and efficiency. If a breakdown or unexpected issue occurs, their quick thinking and problem-solving skills come into play, minimizing downtime and preventing production bottlenecks. While the machines themselves are marvels of automation, it’s the skilled operators who really bring them to life.

Have greater confidence in them

With the advent of artificial intelligence (AI) and machine learning, the plastic injection process will undergo some huge changes. Therefore, we need to view them with more confidence. If you want to know more information, you can check it out on our official website and look forward to cooperating with you.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/09/29

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/09/29

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/09/29

- Topstar Special | National Science and Technology Workers Day 2023/09/29

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC